From the lab to the field to the shop floor, see how Mitutoyo became the leading manufacturer of the most advanced metrology equipment in the world.

Find everything you need to make more informed decisions and advance your business, including Product Announcements, Articles, Case Studies, White Papers, Webinars, seminars and Videos, as well as our Knowledge Base, Mitutoyo Institute of Metrology and M3 Solution Centers.

521 Results

With its automatic angle correction function, the HH-V400 delivers reliable results wherever you work. Perfect for on-site metal testing, maintenance, and quality inspections. Key Features: • Portable rebound hardness testing • Vertical, horizontal, and 360° operation • Automatic angle correction...

Experience the next level of precision with the FTA-H3000, a powerful system that measures both contour and surface roughness in one trace. The new H-3000 Hybrid Detector allows fast, accurate measurements without changing detectors. Designed for speed, automation, and easy...

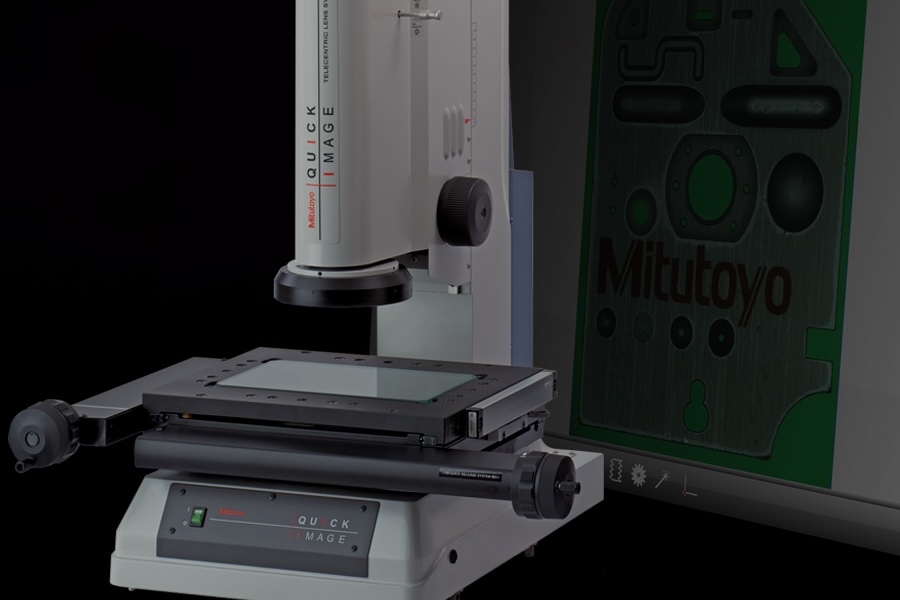

Access the complete Vision Measuring Sytems Section M of the Mitutoyo US-100 Catalog

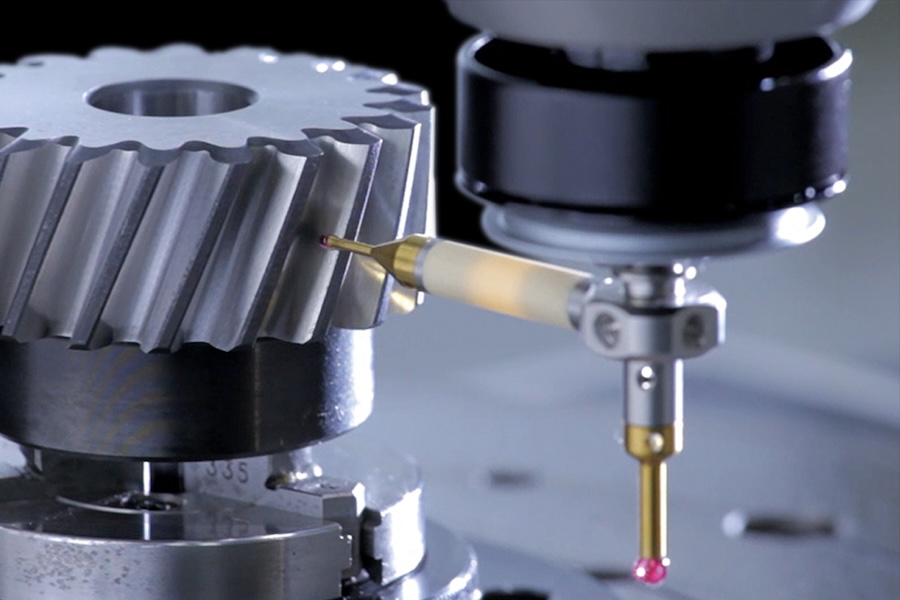

Access the complete Coordinate Measuring Machine Section L of the Mitutoyo US-100 Catalog

Access the complete Test Equipment Section K of the Mitutoyo US-100 Catalog

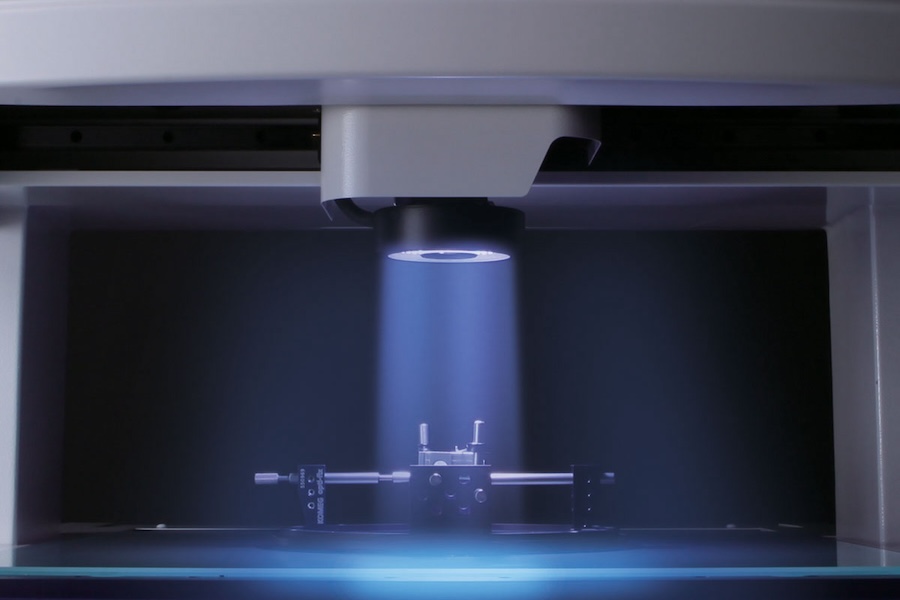

Access the complete Form Measurement Section J of the Mitutoyo US-100 Catalog

Access the complete Optical Measurement Section I of the Mitutoyo US-100 Catalog

Access the complete Scales & DRO Section H of the Mitutoyo US-100 Catalog

Access the complete Sensor Systems Section G of the Mitutoyo US-100 Catalog

Access the complete Small Tools and Data Management sections (A-F) of the Mitutoyo US-100 Catalog

Mitutoyo Precision Measuring Machines Trusted Throughout the World.

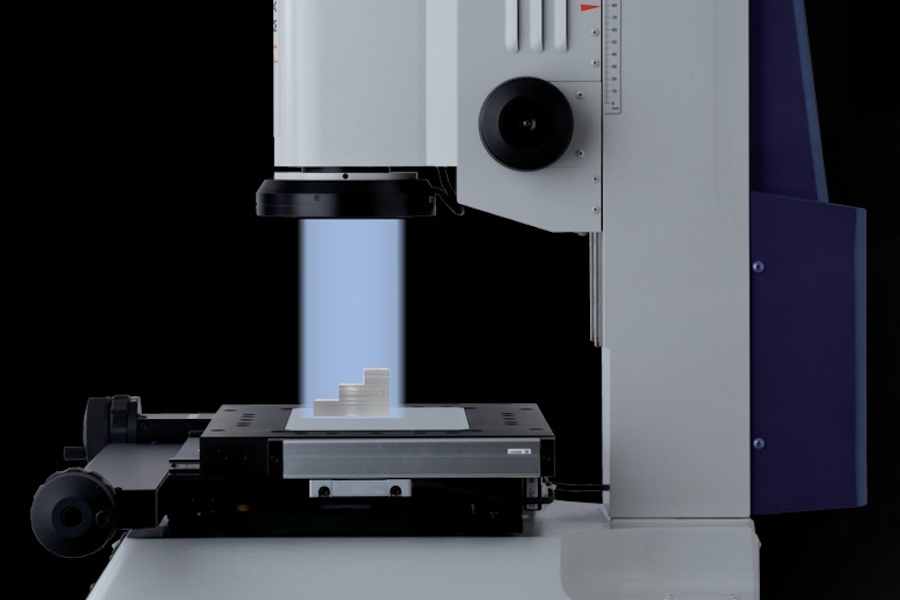

Make measurements simple. Place, click, and measure instantly. QM Fit’s Smart Vision System auto‑identifies parts and shows results in real time. Enjoy a compact design with a wide, comfortable field of view, a long‑focus lens, and an integrated computer. Trace...

Discover how the Mitutoyo TAGLENS with Pulsed Light Source (PLS) delivers ultra-fast focus—up to 70,000 focal changes per second. Capture multiple layers in perfect focus, create high-resolution 3D images, and unlock real-time depth visualization for your microscopy and inspection workflows....

Discover the Mitutoyo Surftest SJ-220 – a portable surface roughness tester designed like a hand tool for easy, on-site use. With a 2.8-inch intuitive touch panel, multiple drive unit options, and optional Bluetooth connectivity via U-WAVE-TIB, the SJ-220 brings precision...

Hungry for precision in food production? From donuts to data, Mitutoyo serves up precision measurement tools made for the food and beverage industry. Whether you’re slicing chips, scanning bread, or tracking quality with data, we’ve got the tech to make...

New protective cases for your tools offer a modern alternative to our wooden cases. Versions include mechanical, standard Digimatic, or QuantuMike-based sets. QuantuMikes are just as accurate as standard Digimatic micrometers, but up to 4x faster. Empty cases are also...

The MDE Quantumike Micrometer offers rapid and precise measurements with its unique wider thread pitch, moving the spindle 2.0 mm per rotation — up to 4x faster than standard micrometers. It features exceptional accuracy with a ±1 μm permissible error,...

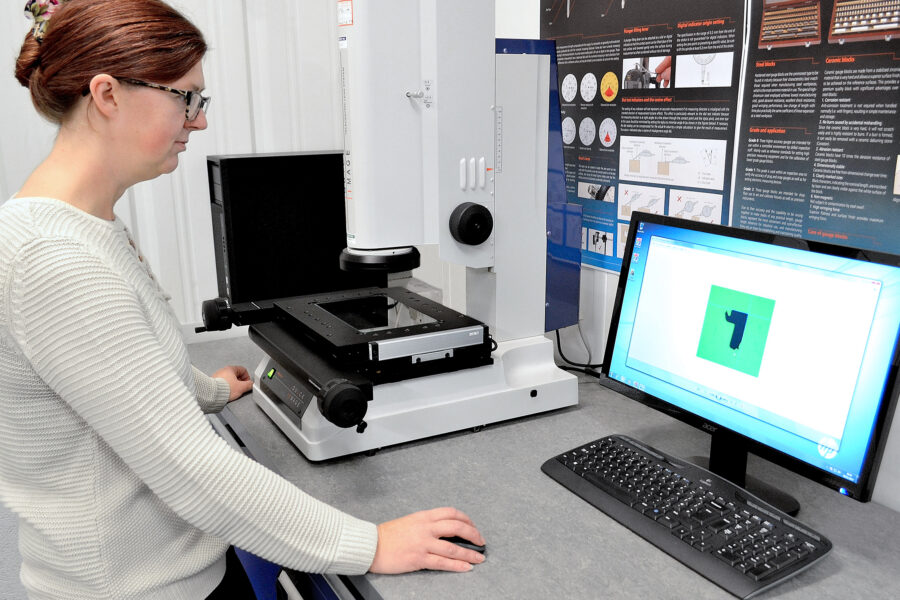

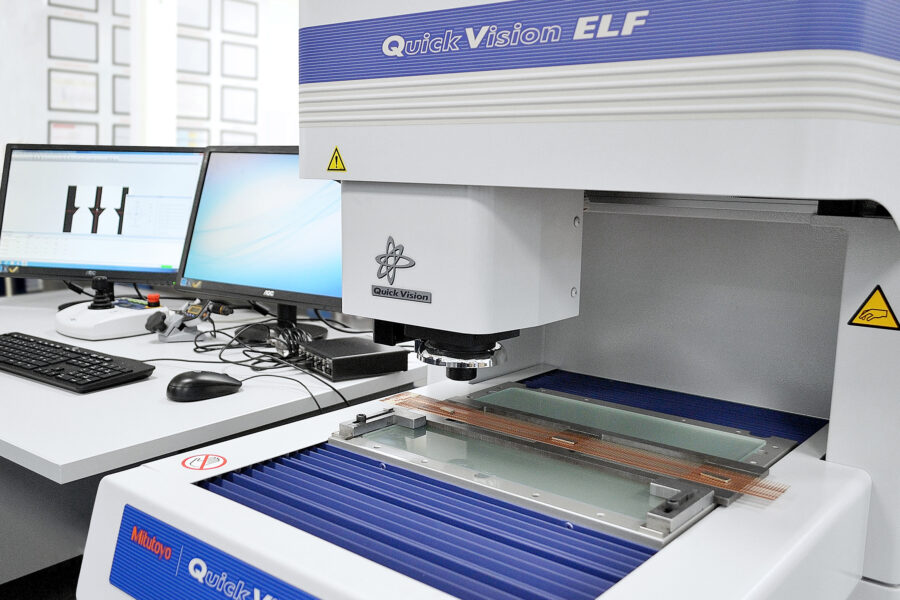

Precision is the bedrock of modern manufacturing, directly influencing product quality, performance, and reliability. At the forefront of this technological advancement is Mitutoyo’s Quick Image series equipped with M3 software.

The landscape of metrology is rapidly evolving, with technology playing a pivotal role in improving accuracy, efficiency, and ease of use. One of the most innovative systems driving this change is the Metlogix M3 software on Quick Image (QI).

When it comes to manufacturing and industrial environments overall, precision when creating components and parts is much more than a luxury or feature.

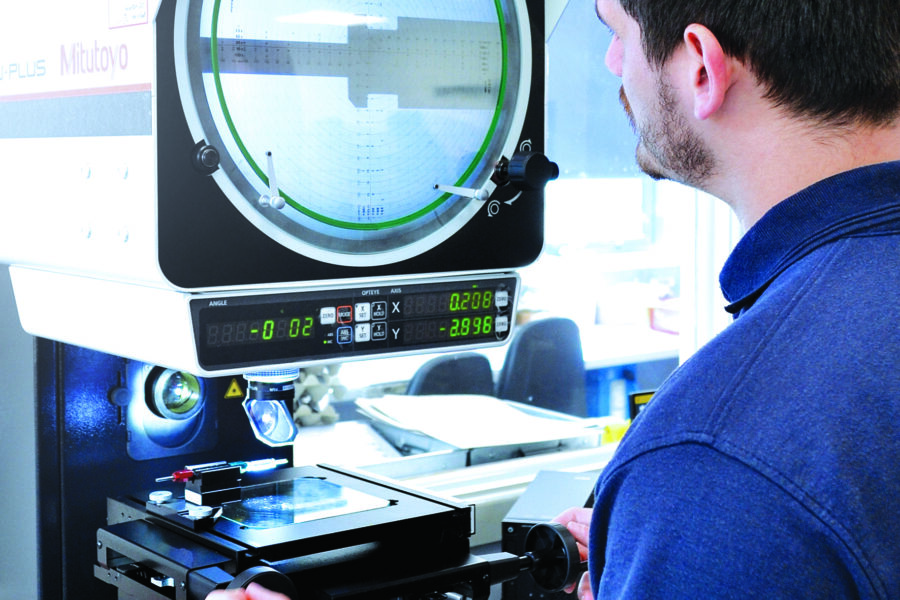

Today, achieving pinpoint accuracy for your parts or product is absolutely crucial. Mitutoyo Profile Projectors are designed to meet the high demands of precision measurement, making them a vital tool for professionals in various industries.

Precision in aerospace manufacturing is critical because even the smallest error can have significant consequences. The industry operates under some of the strictest standards, where components must consistently meet exacting tolerances to ensure safety and performance.

Whether you’re an engineer looking to streamline processes or a manager seeking consistent quality, automation is key to improving both speed and accuracy in gear measurements.

The Metlogix M3, now integrated with Mitutoyo Quick Image systems, creates a powerful combination that brings the latest advancements in metrology to the forefront of precision measurement, offering users an unprecedented level of accuracy and efficiency.

No matter what you are manufacturing, efficiency and precision are essential to ensuring high-quality production while minimizing waste. State-of-the-art precision measurement solutions, specifically the MiSTAR 555 CNC CMM, LH-600F linear height gage, and QI/QS Vision Systems, provide remarkable enhancements to...

The Mitutoyo QV-Active 202 vision system stands as a testament to precision engineering and meticulous craftsmanship. This advanced non-contact 3D measurement tool represents the commitment Mitutoyo has for precision measurement.

Precision measurement technology has evolved significantly over the years, driven by the need for greater accuracy and efficiency in various industries.From traditional mechanical tools to advanced digital systems, these technologies play a critical role in ensuring quality and precision in...

High accuracy, low uncertainty, and validated measurement methods are the reasons customers rely on Mitutoyo America Corporation.

Introducing the new ID-C Digital Indicator! Control settings from your computer, enjoy a large display with max/min range, and perform tolerance functions with go/no-go judgment. Key features include a 330-degree rotatable display, function lock, and calibration warning. Enhance your measurements...

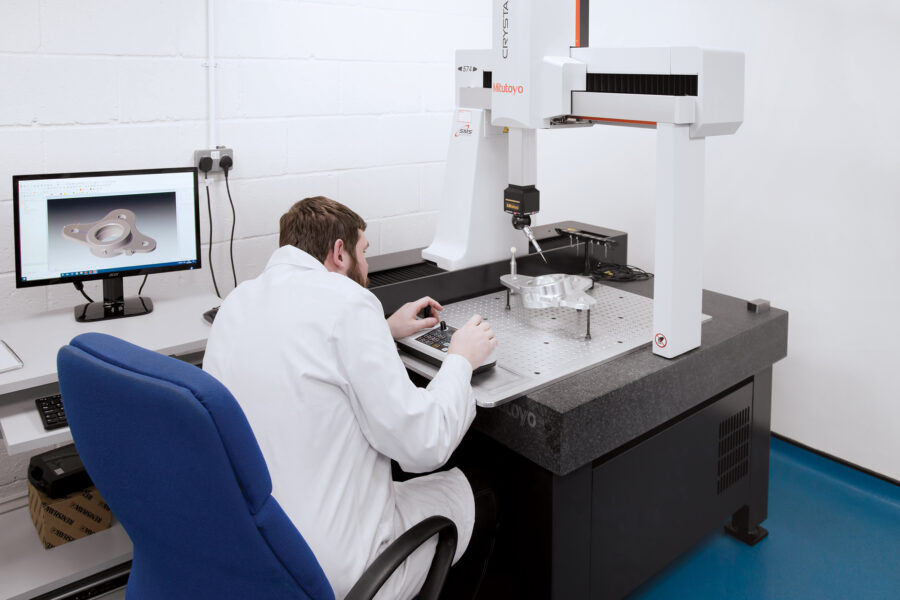

Watch Titans of CNC install their new CRYSTA-Apex V CMM from Mitutoyo.

The versatile Mitutoyo Rockwell Hardness Line-up includes models designed to accommodate any budget without compromising on quality or functionality. All models, including the HR-430 series, are equipped with an Automatic Brake and Process initiation system, which automatically applies your desired...

We are taking a closer look into how Mitutoyo Indicators, including digital, dial, and test indicators contribute to manufacturing success to enhance product quality and boost operational efficiency.

Spring is here, and with it comes discounted prices and special deals from Mitutoyo America in our 2024 Spring Promotion!

The transition of metrology from basic measurement instruments to sophisticated analytics platforms represents an unwavering commitment to accuracy and reliability. Central to this evolution is an intensified focus on data analytics.

The LH-600F is a user’s dream, equipped with a state-of-the-art touchscreen interface. Designed for simple and intuitive operation, measurements are achievable with a press of a button or a tap on the touchscreen icon.

The Quick Scope QS-L system is a fully-featured, vision measurement system featuring a space-saving ergonomic design.

MeasurLink® Version 10 is an easy-to-use, data collection and real-time statistical process control suite. MeasurLink® supports Real-Time data collection with live SPC charts to alert operators, and additional alerts, analysis tools, and reports for Quality Control and Operations.

The Mitutoyo LH-600F series Linear Height Gage represents the cutting-edge of 2D linear precision measurements. With unparalleled features and exceptional accuracy, the LH-600F revolutionizes the world of measurements, offering a host of advantages to professionals across diverse industries.

Choosing the right microscope for your application is no small feat. It’s a decision that requires a deep understanding of the task at hand and the tools available to you. From magnification to resolution and from ease of use to...

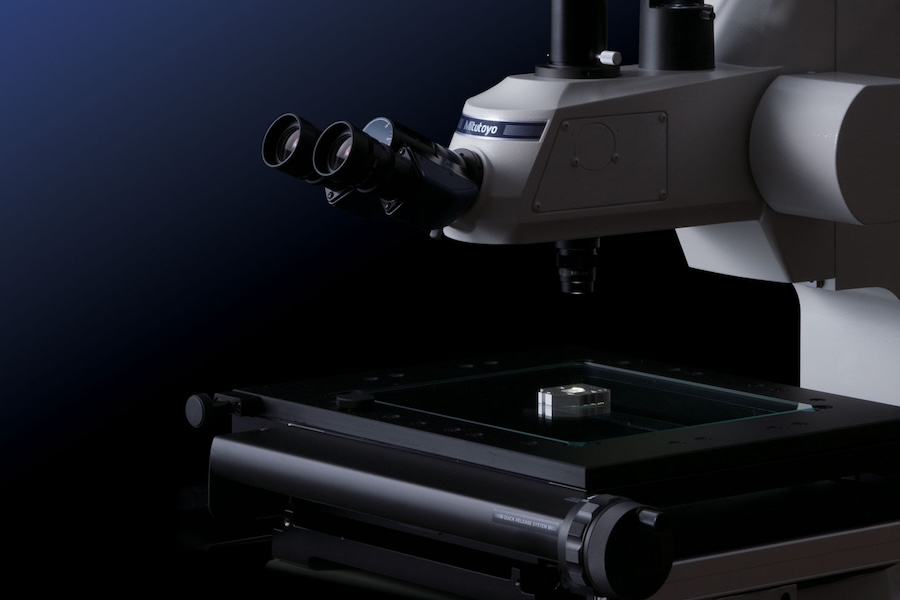

Today’s manufacturing industry is a battleground where precision, efficiency, and quality control aren’t just buzzwords, but vital lifelines for survival. As such, the MF and MF-U series of microscopes from Mitutoyo aren’t just tools – they are game-changers, designed to...

With this limited-time program, your move to a new, state-of-the-art Mitutoyo Roundness Measurement System could not be easier, faster or more budget friendly.

Sensors and Embedded Equipment provides an in-depth overview of their extensive range of sensor products, their diverse applications, and the industries that benefit from these cutting-edge tools.

Since 1934, Mitutoyo has been committed to producing high-quality, affordable measurement tools for manufacturing applications of all types. Today, Mitutoyo is the benchmark brand for calipers and other measuring tools.

Tune into this video with Unbox Therapy as they use Mitutoyo Calipers to precisely compare the current iPhone 14 Pro Max to a potential iPhone 15 mockup!

In this video, we take a deep dive into Mitutoyo’s commitment to quality. From micrometers to CMMs and vision machines, we explore how Mitutoyo’s dedication to precision and accuracy drives their innovation. Learn how Mitutoyo’s in-house development and manufacturing processes...

Measurement solutions for a wide range of fields in the semiconductor manufacturing industry, which is growing rapidly following a shift to production of electric vehicles, expansion of services in line with the implementation of 5G, etc.

Mitutoyo offers solutions to measurement of a wide variety of lenses from research and development to pre production and mass production.

Mitutoyo offers solutions to measurement of a wide variety of electric vehicles from research and development to pre production and mass production.

To help the thousands of operators using legacy CMMs, we are pleased to offer a U.S.-based trade-in program. When you trade in your current CMM and purchase a new Mitutoyo CNC CMM, you will receive the latest technology, ensuring reliable...

New-generation ID series making measurement operations smoother and enhancing production quality.

Tyson and Travis take their next facility tour in Japan, at Mitutoyo’s Kawasaki facility. Here they go through several different manufacturing stations and learn the history of Mitutoyo, from where Mitutoyo started and where they plan to go in the...

Join Titans of CNC as they tour a Mitutoyo factory in Hiroshima, Japan. With never-before-seen footage, grab a closer look at Mitutoyo precision and dedication.

From manual and automated to advanced and system-based systems, Mitutoyo offers a full line of Vision Measuring Machines that are highly accurate, built with quality components and feature the latest in optics technology.

With sophisticated edge detection capabilities, an illumination wizard, and advanced user-friendly software, the Quick Vision Series satisfies the demand for compactness, high accuracy, and vast performance in the field of non-contact dimensional measurement.

The 2-D non-contact Quick Image vision system features better operational efficiency and productivity, reliable quality and easy-to-use functions while providing highly accurate measurements.

This technical bulletin provides an example evaluation of measurement uncertainty for the calibration of a caliper in accordance with ISO 13385-1 (ASME B89.1.14) and ISO 14253-5 (ASME B89.7.6)

The MiSCAN Vision System has a multiple sensor microscopic-form measurement system, using combined technologies of coordinate and vision measurement system technology.

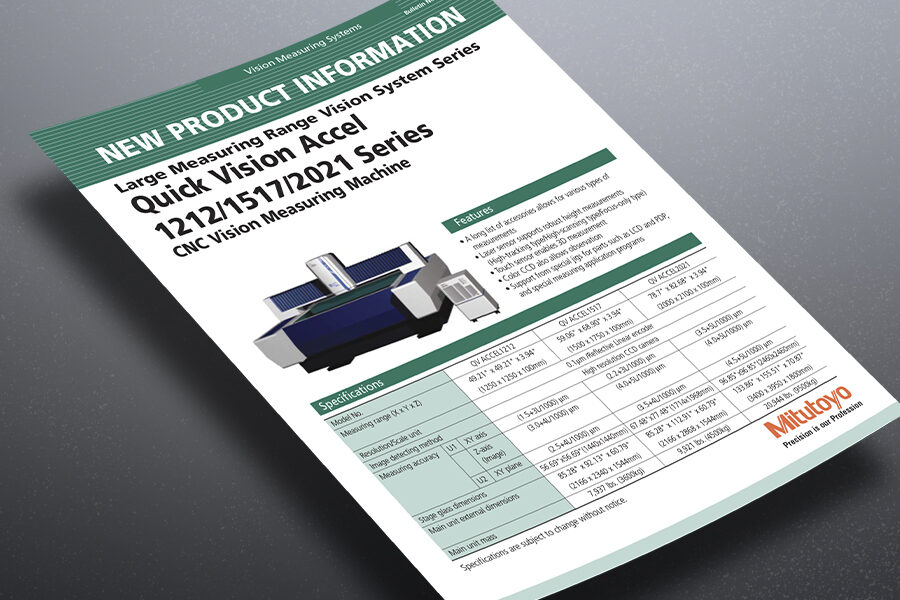

The large-format Quick Vision ACCEL CNC vision measuring system’s moving-bridge structure moves the X- and Y-axes faster for better measurement speed and efficiency.

For more than three decades KOMEG has been among the international innovation generators of sophisticated industrial measuring technique, setting important technological milestones and providing groundbreaking customer-specific solutions.

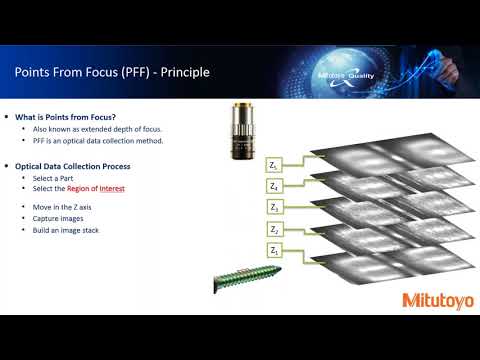

Points From Focus (PFF) is a Mitutoyo-developed optical data collection method that captures point data by focusing in the Z-axis.

Tyson and Travis take a NEVER BEFORE SEEN tour of just one of the Mitutoyo manufacturing facilities in Japan. In this video we explore the Utsunomiya facility, and take a good look at the manufacturing process of CMMs and calipers.

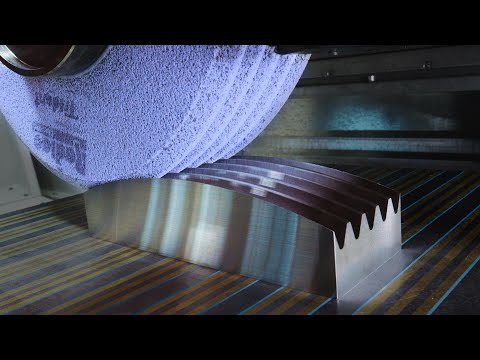

Tune in with Chris, from Titans of CNC, as he tests the Vitrified Diamond wheel from Tyrolit on 5 different materials using the Studier S41.

Titans of CNC ask the question “Is a Metal 3D Printer capable of running production?” as they try to mass produce titanium bike levers using a 3D printer.

Jessie, from Titans of CNC, discusses HSS tooling and how going the cheap way… is actually costing you more than just money.

Watch Barry, with Titans of CNC, as he creates a complex aerospace bulkhead fitting using custom tooling.

Mitutoyo’s History of Precision Measuring Instruments brings you a closer look at the history of calipers.

Follow the process as Trevor, from Titans of CNC, uses a Wire EDM from ONA to Machine Tungsten Carbide Perfectly.

Chris shows us the fundamentals of OD Grinding on the Studer S41 CNC Machine from United Grinding, using Tyrolit wheels.

Trevor shows us the entire process to create graphite electrodes using the ONA Wire EDM… He then uses it to cut deep cavities into Steel on the ONA Sinker EDM.

Jessie mills and grinds 4140 Heat Treated Steel into a part he’s wanted to create his entire career. The contour milling was done on the BVM 5700 from DN Solutions. The grinding operation was suggested to be impossible…

We are glad that you’re a fan of our Borematic Bore Gage, @AdamSavage. We’re sure some day you’ll find the perfect use for it.

The Series 570 Absolute Digimatic Height Gage. A New standard height gage providing reliable and smart measurement. This is an update of the height gage standard type that has gained a strong reputation in the manufacturing field.

For a limited time only, download a copy of the latest book on Test Uncertainty, and learn about the evaluation of measurement uncertainty in the calibration and conformity assessment of measuring instruments.

With multiple system configurations, enabling real-time measurement and data management, Mitutoyo is revolutionizing inline manufacturing with our high accuracy LG100, LG200 series, and the EJ Counter interfaces

Mitutoyo’s newly redesigned Quick Vision Pro Machines offer the next evolution in non-contact inspection. These new machines build on Mitutoyo’s tried and true Quick Vision platform and offer faster inspection with the same superb accuracies as previous models.

Industrial inspection and quality control rely on precision measuring machines and precision fixturing alike. Reliable and repeatable fixture set-up is a basic requirement for successful and accurate measurement. Mitutoyo fixtures: For measurably better results.

The RTX Roundtracer Extreme is a revolutionary all-in-one measuring system, providing highly accurate and efficient roundness, contour, surface roughness, twist, and 3D analysis on workpieces with various geometries in a single machine, saving time and improving productivity. Designed with a...

As the scale moves with respect to the detector, the intensity of the light passing through the window in the index scale varies constantly.

Chris takes O2 Hardened Tool Steel on the Studer S41 and grinds a 12 sided and 16 sided polygon into a cylindrical work piece. He gives insight to the programming of High Speed Form Grinding.

Barry uses a Mitutoyo indicator to indicate and square his vice before using the Doosan 5700L to Machine the Perfect BALL in a BOX. He reveals his secret method of machining a free floating object. Trevor helps out by printing...

New video from TITANS of CNC MACHINING. Jessie Takes a MASSIVE 1″ grind on our Blohm from United Grinding. Using a specifically dressed Tyrolit wheel, Jessie and Chris do what we have all been waiting for.

Checking square with a Mitutoyo indicator.

Biggest Fastest CNC Machining Cuts Ever Taken with a 3.0” Dia Shell Mill. Watch as the Blaser Synergy 735 Coolant goes on and the 100 HP Ibarmia 5 Axis Pushes The Kennametal 5720 Shell Mill Past The Limits.

Using our Doosan DNM 5700L and our Kennametal Tools, Titan shows us how to machine Delrin Plastic like a Pro!

Jessie uses our Blohm Planomat XT from United Grinding. Using Tyrolit and Radiac grinding wheels accompanied with diamonds, he creates impossible grooves!

MCubeMap Ver. 9 is 3D surface analysis software for surface roughness and vision measuring machines. Clear imaging of analyzed data using diverse computer graphics technologies.

Rockwell hardness testing machine series, 3 models to suit practically every application. HR-320MS is a Dual type hardness testing machine, HR-430R is a Rockwell hardness testing machine and the HR-430S is a Dual type hardness testing equipment.

Mitutoyo caliper winner announced.

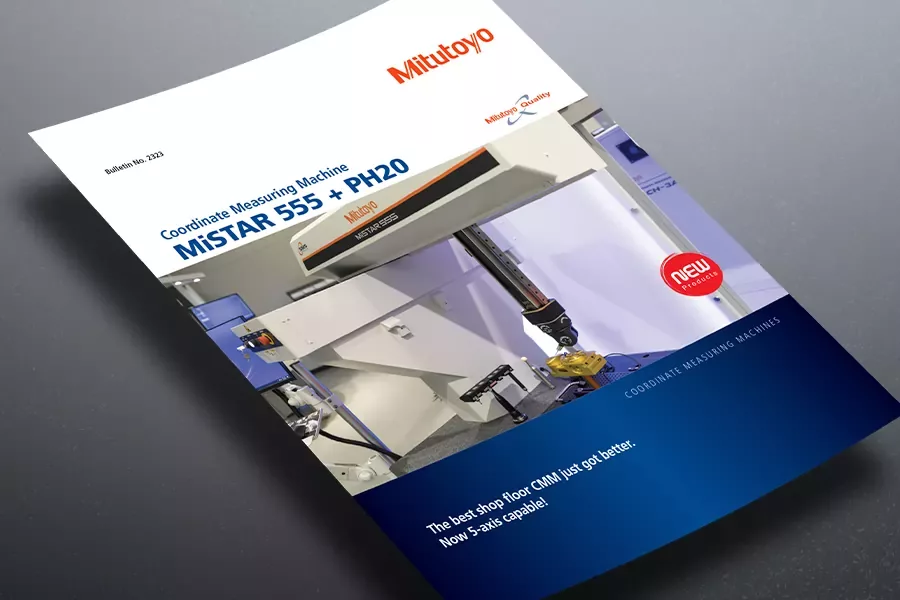

The best shop floor CMM just got better. Now with 5-axis measuring, allowing increased throughput with reduced calibration time. PH20’s unique ‘head touches’ allow measurement points to be taken by moving only the head rather than the CMM structure.

TITANS of CNC MACHINING demonstrates the surface finish results of a conditioned grinder wheel using a high feed rate.

The Mitutoyo PJ-Plus is a new series of profile projectors that utilize LED lighting and provides reliable measurements in manufacturing site environments.

Mitutoyo – Travis teaches you how to inspect flatness using 40 year old jack stands.

This weekend’s project is a recovery from a recent mistake, as Adam has to undo a his first attempt at cleaning his set of micrometer screw gauges in which he used too much oil! Fixing that screw up is going...

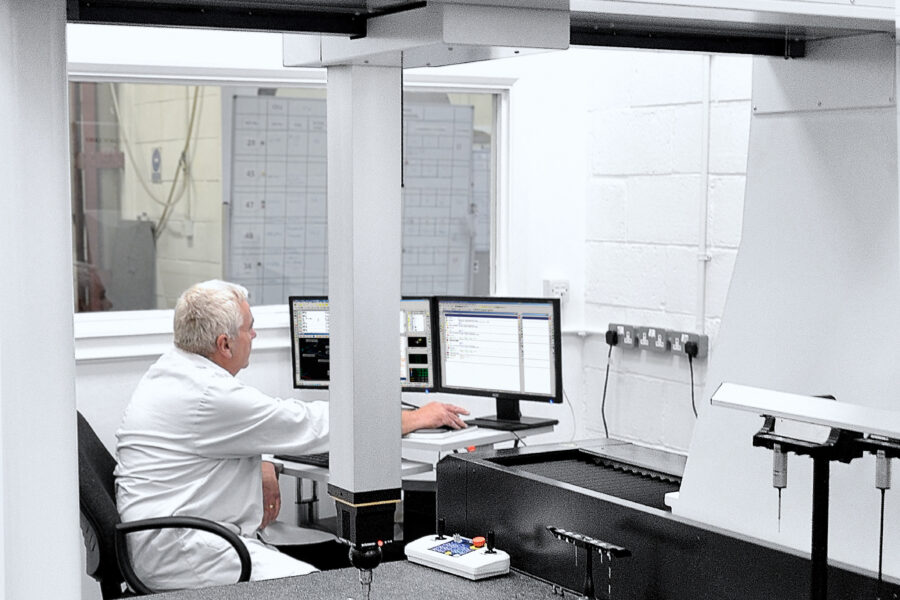

Mitutoyo were at Southern Manufacturing demonstrating the latest in metrology innovation. The stand featured numerous non-contact measuring solutions in vision and form machines, SPC software and an inline shop-floor CMM and robot.

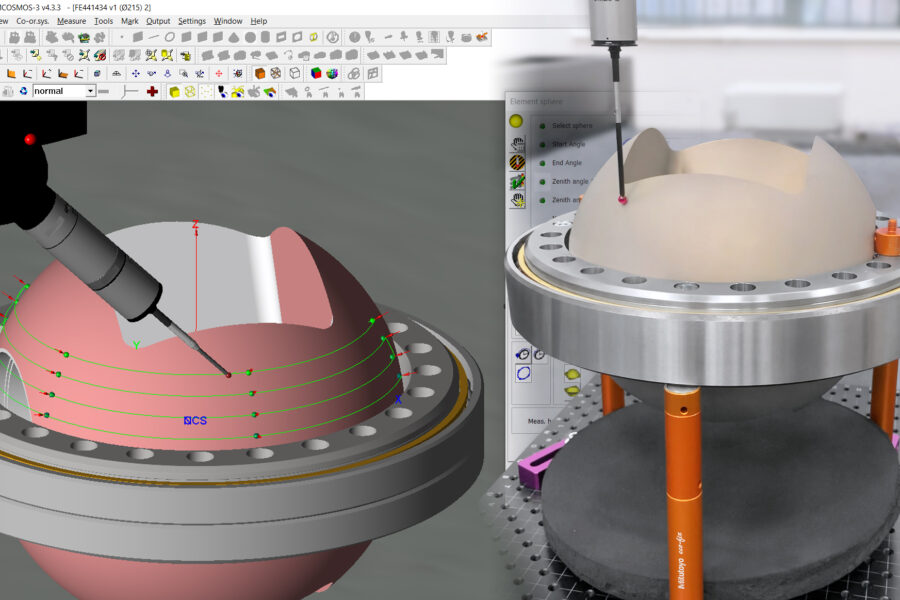

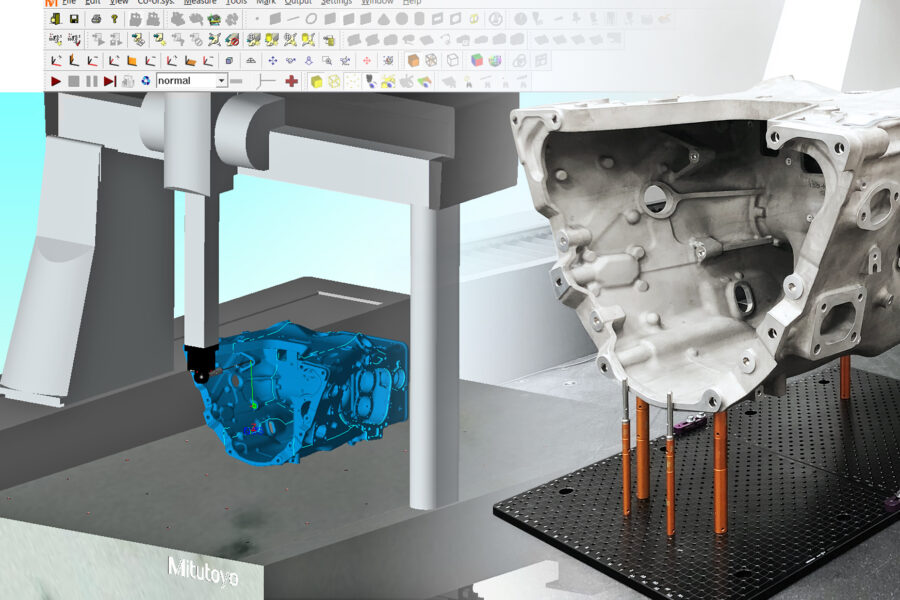

With MCOSMOS, your coordinate measuring machines become efficient information centers – powerhouses of design, production, and quality control. Streamlined measurements, as well as convenient and reliable data, are at your fingertips throughout the production process.

We have a major investment at Area 419 into metrology and related tooling, and we wanted to keep it protected and organized. See how we did it.

Adam’s in a metrology state of mind this week as he sets out to organize his collection of machining gauge blocks and gauge pins, to be kept alongside his mill. That means it’s time for another shop infrastructure build–the first...

As Adam gets back into machining projects and exercises, he takes a moment to share one of the most interesting tools in the shop: a set of Mitutoyo ceramic gauge blocks used for precision measurement. To explain how and why...

With its high-resolution scale load cell developed uniquely by Mitutoyo that allows for high-precision test load feedback control and state-of-the-art design that delivers both aesthetics and usability on the ground, the new HR-600 Series enables hardness testing that defies conventional...

Roundtracer Flash is the perfect solution for accurate quality control in the laboratory as well as in the production environment.

High scanning rate (3200 scans/sec) and high accuracy, non-contact measuring systems, the laser scan micrometer (LSM) inspects small, fragile workpieces at a high temperature, even while in motion or vibrating.

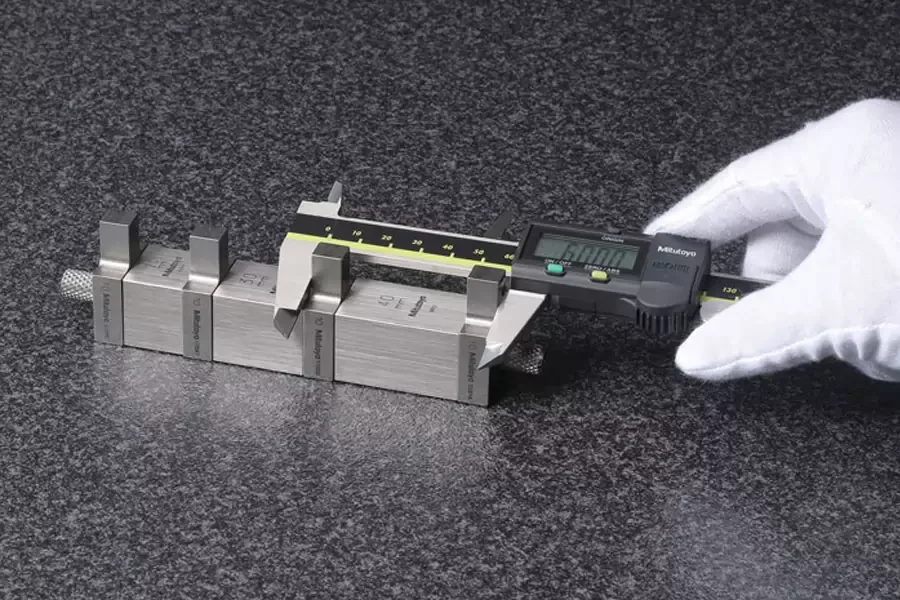

Since the use of gauge blocks helps an organization to demonstrate traceability to national length standards, gauge blocks are in widespread use in corporations, universities, and laboratories throughout the world.

Learn more about the Micrometer and its deep history ranging from The Early Period to the next generation of Micrometers!

This literature is an educational guide to the essential technical information associated with a variety of Mitutoyo precision tools and instruments.

This booklet provides guidance on the proper use and maintenance of a variety of dimensional measuring instruments.

This literature is an educational guide to the basic technical information associated with a variety of Mitutoyo precision tools and instruments.

In this video, we’ll discuss the top 5 MeasurLink software tips you need to know for efficient data collection in your shop.

The Metrology Handbook 2nd edition is the most modern reference book available in the dimensional measurement and metrology field. This 280 page, full color book was written by Mitutoyo America’s own Nobuo Suga. The entire book is available for viewing...

One of the most dependable and affordable ways to set up a Mitutoyo M-Plan microscope objective for macro photography is by creating a conjugate system with the remarkable 208mm Raynox closeup filter as a relay lens. But as usual, the...

Learn how to use the security module in this MeasurLink training video to help protect your data.

The Mitutoyo M-Plan Quick Start Guide Think of this video as the big sheet of drawings that falls out of the box when you buy some new tech gadget. The device will be obsolete before I have any idea how...

There are a LOT of items that you’ll find on a reloading bench, but what items do you really *need* to have?

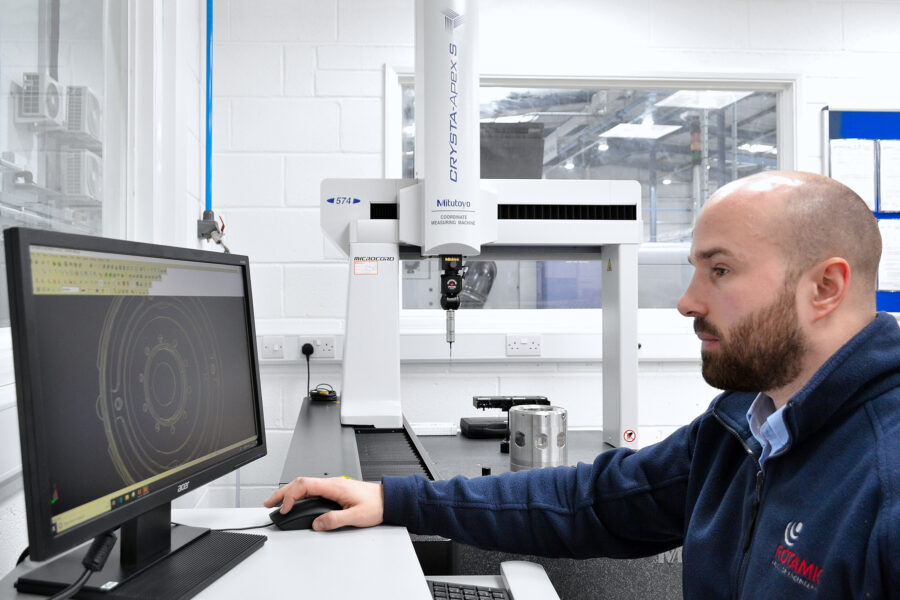

Using this specific CMM in our current CNC Machining production run is making life easier for our machinists. We tell you why and show you how…

As even the smallest numbers of contaminants can multiply during the brewing process, ensuring that outstanding levels of hygiene are maintained is vital to the effective production of quality beer. The avoidance of contaminants helps to guarantee the delivery of...

The Mitutoyo M Plan Apo 5X for Macro Photography – the lowdown This objective simply can’t be as good as everyone says it is – not at that price. The competition are having to charge thousands of dollars for lenses...

Join us for our LIVE event “Hardness Testing Equipment Product Line-Up” streaming on YouTube & Facebook at 11am CDT! Make sure you are listening! When you hear Curtis say our secret phrase, text it to (281) 217-1864 for a chance...

With operations in 26 countries Tata Steel is one of the world’s most geographically diversified steel producers. Based in Glamorgan, South Wales, Tata Steel’s Port Talbot plant is capable of producing nearly 5 million tons of steel slab per annum...

With a history stretching back over 100 years, the classic profile projector remains an indispensable piece of metrology equipment. Amongst other reasons, the profile projector’s enduring popularity is due to its continuous technical evolution. Over the past century a wide...

The Mitutoyo MF and MF-U measuring microscopes are available in manual and motorized units. Each model is packed with features, functions and high magnifications for highly accurate measurements on miniscule-sized parts.

As the world’s leading manufacturer of precision measuring equipment Mitutoyo offers a comprehensive variety of metrology products, ranging from the humble caliper to advanced vision measuring systems and 3D coordinate measuring machines. Now in its 40th year of operation, Mitutoyo...

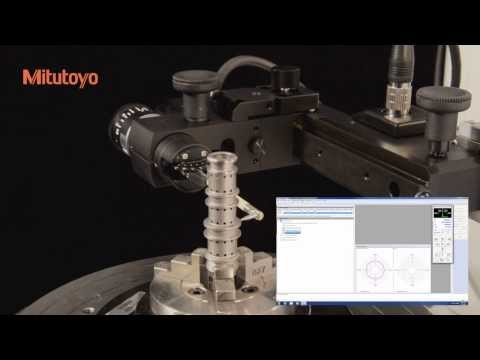

Today we discuss the range of VMM’s on offer from Mitutoyo with Regional Sales Manager Chris Pullen. Chris and Mark discuss the range from the small Quick Image right through to the MiSCAN which features sub-micron accuracy with the MPP-Nano...

The Mitutoyo Technology Solutions Group takes the well-established Points From Focus (PFF) technology to another level with a high-speed 3D imaging system. PFF is a 3D measurement technology which uses a stack of images in the focus direction to create...

Xtrac is the World’s leading supplier of high-performance transmissions for top level professional Motorsport and High-Performance Automotive applications. Headquartered in Thatcham, Berkshire and with additional operations in the USA, Xtrac designs, manufactures and assembles all of its transmissions in-house using...

In this video we look at different applications of surface finish measurement and compare the uses of a skidded versus a skid-less system.

High-precision protractor makes accurate angle measurements on machines, molds and jigs and can be attached to a height gage.

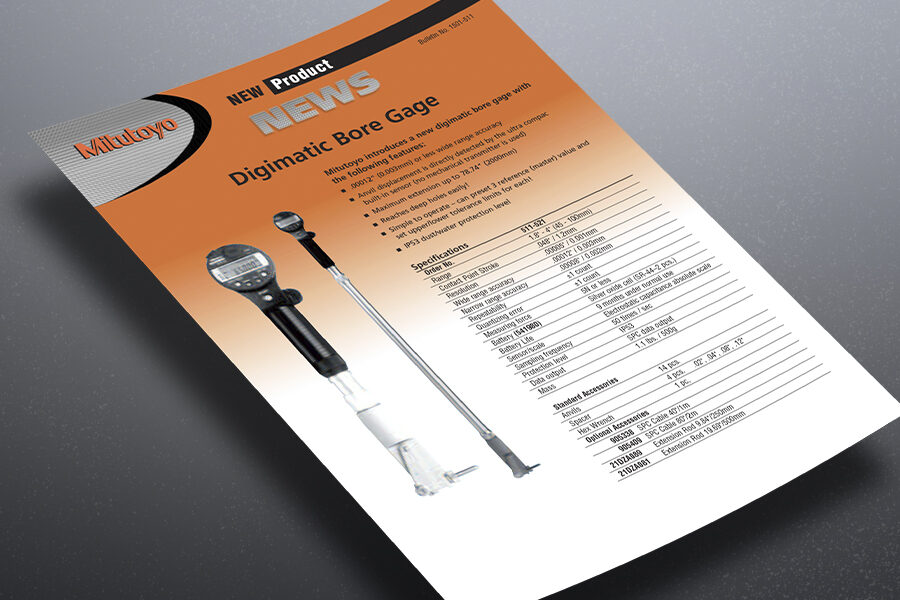

The simple-to-operate Digimatic® Bore Gage is exclusively designed to take ID measurements that are shown on a digital LCD display built into the instrument.

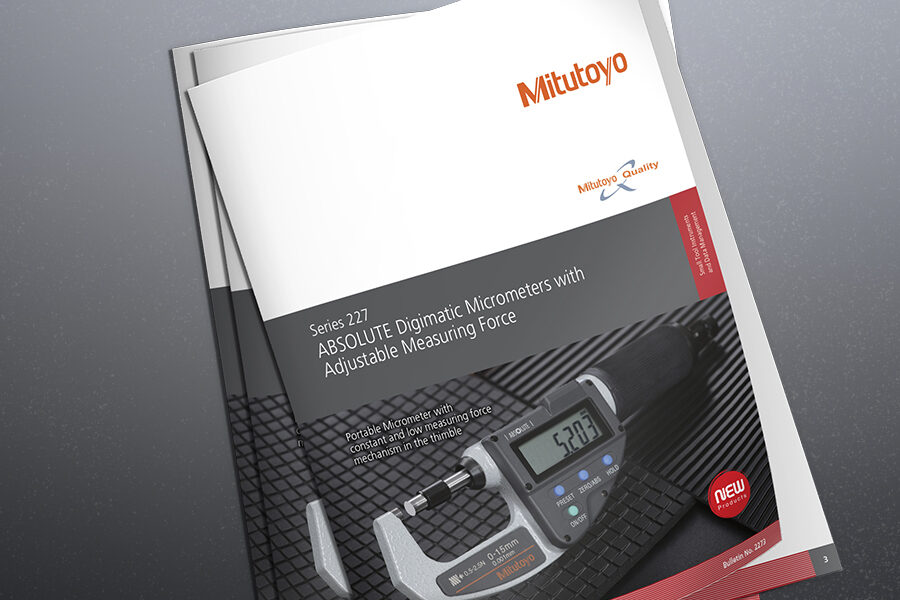

Portable Micrometer with constant and low measuring force mechanism in the thimble.

A new generation, one-handed operation, outside micrometer. Easy, accurate, and reliable – even for inexperienced users.

ABS coolant-proof caliper with dust/water protection conforming to IP67 Level. Can be used in workshop conditions exposed to coolant, water, dust or oil.

Inside/outside diameters, maximum/minimum heights, and displacement can be measured using a standard probe.

High-accuracy Holtest Series micrometers make three-point / two-point bore diameter measurements.

Equipped with “speed” enabling higher measurement efficiency, “operability” with automation and a wide variety of features, and expandability which offers upgrading to a complex system by incorporating optional detectors, this revolutionary measuring system defies conventional thinking.

All models are complete with Flat and VEE anvils, diamond and carbide ball indenters, and Rockwell blocks. The new frame design allows for a 7.1” specimen capacity.

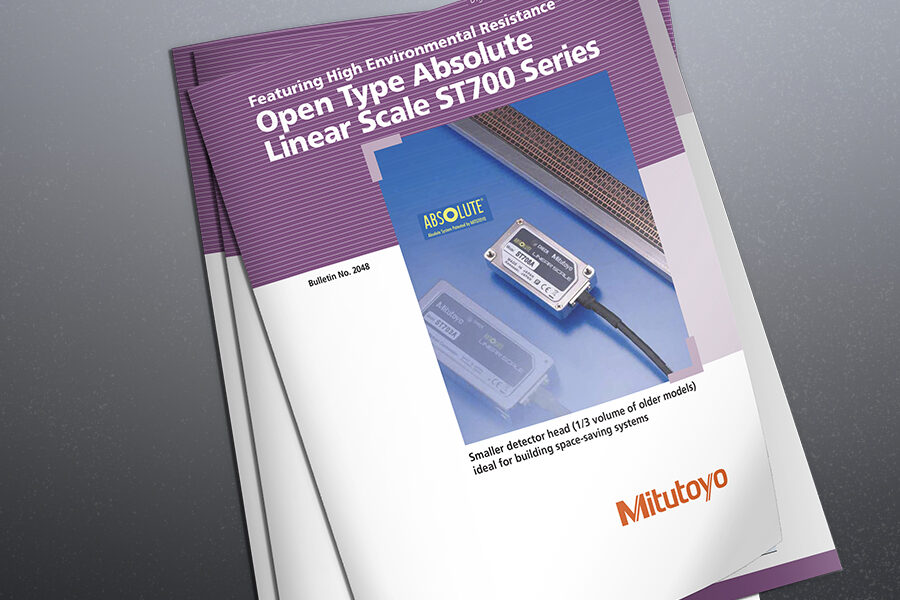

Mitutoyo’s Linear Scale Systems tightly couple linear scale units with dedicated digital readout (DRO) units in order to accurately detect and display displacements for machine tools, measuring tables, 3D printers, XY tables, or any application requiring measured lengths or accurate...

The inherently non-contact measurement method of profile projectors makes this type of instrument highly suitable for measuring small parts that are unmeasurable with general-purpose contact instruments or plastic parts that are easily deformed.

DRO Retrofit Packages include all the components needed to accurately detect and display linear displacements on milling, grinding and lathe machines. Retrofit packages are available in many different sizes and types for 2- and 3-axes machines.

Designed for customers that manufacture and measure on a timed measurement schedule, Collection Scheduler works in conjunction with any Real-Time edition to alert operators when the next measurement is due with a colorful Andon display and timer.

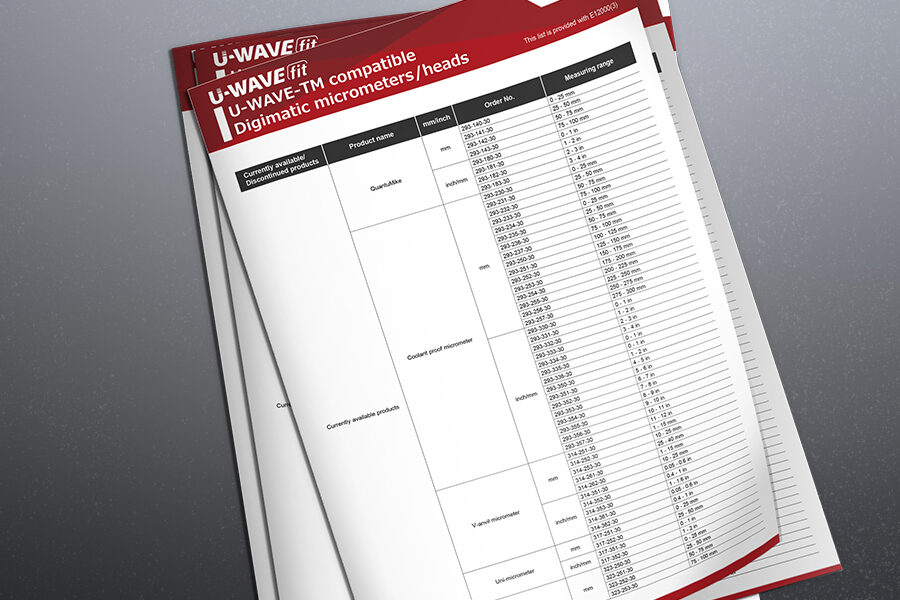

The new U-Wave Bluetooth transmitter utilizes a different wireless technology than the U-Wave and U-Wave Fit products. Please reach out to your local sales representative or www. mitutoyo.com for more information about any of these products.

MeasurLink® is Mitutoyo’s Data Collection and Real-Time Statistical Process Control Software. MeasurLink® can be used in any industry to manage inspection data collection and improve manufacturing processes.

Collect data quickly and easily with any of Mitutoyo’s Data Management products. Whether your need is to manage and retain incoming data, gather data from multiple tools to create a customer report, perform SPC, or simply send data into Excel,...

Must register on our end user portal to access this literature.

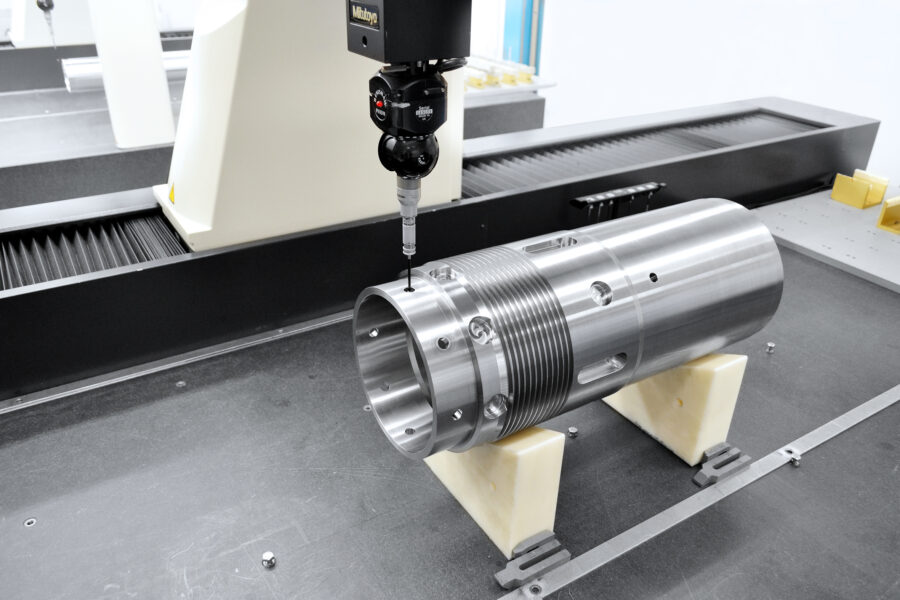

The CRYSTA-Apex V Series is a new generation CNC coordinate measuring machine that helps make the smart factory—a factory that leverages IoT for the advanced management of production and quality information—a reality.

The MiSTAR 555 Shop Floor CNC CMM is a highly environment-resistant Coordinate Measuring Machine, that allows shop-floor inspection outside the measuring room. With a user-friendly design that reduces the operator’s workload.

Mitutoyo has long been a worldwide leader in precision measuring instruments and solutions. Because we are committed to helping you achieve 100% defect-free products, we used artificial intelligence to develop a simple method for the complex problem of defect detection....

The Mitutoyo RoboTAG is an optical measurement sensor designed to mount on robots and allows high-speed acquisition of images from multiple focal lengths. This new technology paves the way towards high-speed in-line inspection and optical measuring. Designed by the Mitutoyo...

Watch Titans of CNC install their new CRYSTA-Apex V CMM from Mitutoyo.

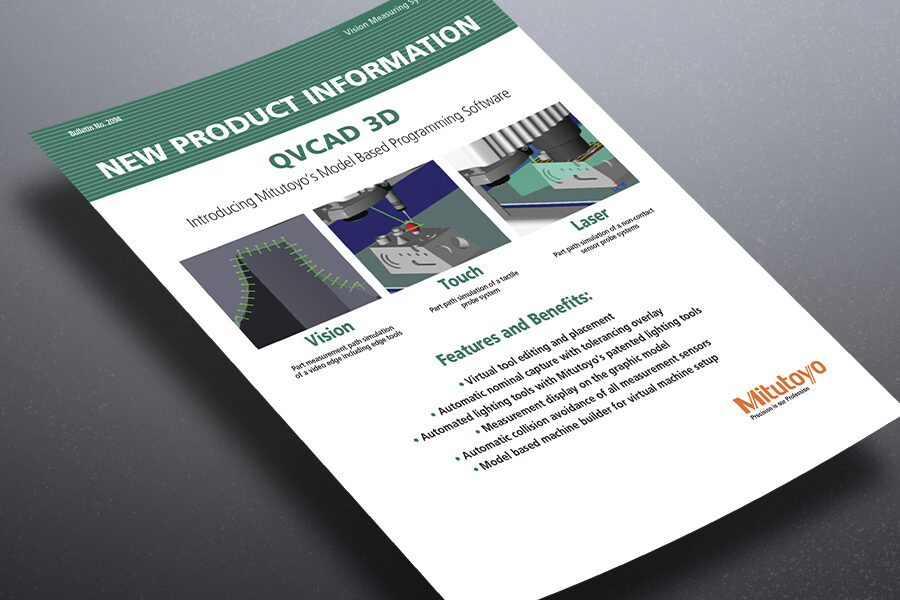

Mitutoyo Quick Vision Systems are capable of accurate non-contact, high-throughput measurements. With QV3DCAD software, Mitutoyo Quick Vision Systems can be programmed from 3D solid models either at the machine, remotely, or completely offline.

To aid in his machining projects, Adam recently picked up a full set of micrometer screw gauges–precision calibrated tools for measuring his machined parts and components. Today’s One Day Build is a deep dive into how measurement affects machining processes...

The Resistance of Indentation Hardness Testing Forum Live Event presented by Mitutoyo America Corporation.

Muffett Gears can trace it origins back over 100 years. Remaining in Tunbridge Wells, Kent, the town it was established in, the business has grown into what is now a world-class manufacturer of precision gears and related components. The company...

In our live Ultra Precision Laser Scan Micrometer Forum, Michal Grosenbach and Curtis Stubbs give hands-on demonstrations of the latest Mitutoyo LSM’s and how to overcome your dimensional challenges. They cover diameters, gaps, run-out, TIR and much more!

The FORMTRACER Avant Series form measurement system is a hybrid type surface texture metrology system that can measure both surface roughness and contour all within one system with high-accuracy and speed.

The new U-Wave Bluetooth wireless data collection transmitter utilizes a different wireless technology than the U-Wave and U-Wave Fit products. Benefits include: • No receiver required – Measurement data can be sent directly to a PC with Bluetooth®, Tablet or...

The Quick Image System from Mitutoyo records measurements lightning fast. Travis & Mike Demonstrate the process. Find more info about the Quick Image here: http://bit.ly/MitutoyoQuickImage

Want to see what we’re up to at our very 1st “LIVE” Virtual Trade Show? Watch this short video and then check out our FREE Virtual Tradeshow at https://tradeshow.mitutoyo.com/.

All of us at Mitutoyo America Corporation miss you, so we are inviting you to join us for our very 1st “LIVE” Virtual Trade Show. This event will give us the opportunity to gather together for 4 days to participate...

This technical bulletin was developed to help owners of measuring equipment reduce risk and optimize their expenses in calibration. All measuring equipment requires calibration; however, there are many different types of calibrations which can lead to false assumptions and missed...

The new CRYSTA-Apex V Series from Mitutoyo, which delivers faster measurements without compromising the measuring machine’s inherent accuracy. It also supports measurement of workpieces of many different shapes, including impellers and blades. The CRYSTA-Apex V Series is a new generation...

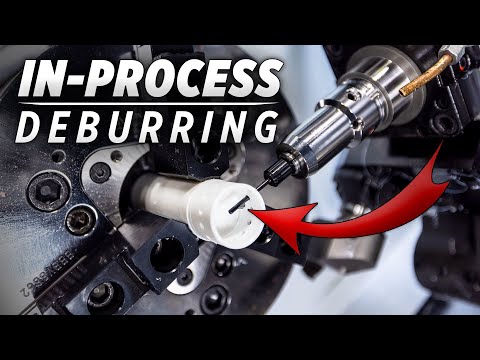

As final inspection is usually the last process undertaken before manufactured components are dispatched, delays in this important activity can squander any time savings and efficiencies gained through the use of highly-productive CNC machine tools. Similarly, when performing in-process inspection...

Over recent years, Torbay, Devon, has grown to become an internationally renowned centre for the electronics and photonics industry. In addition to global technology businesses, many smaller advanced electronics companies are located in the area. To support this burgeoning, high-tech...

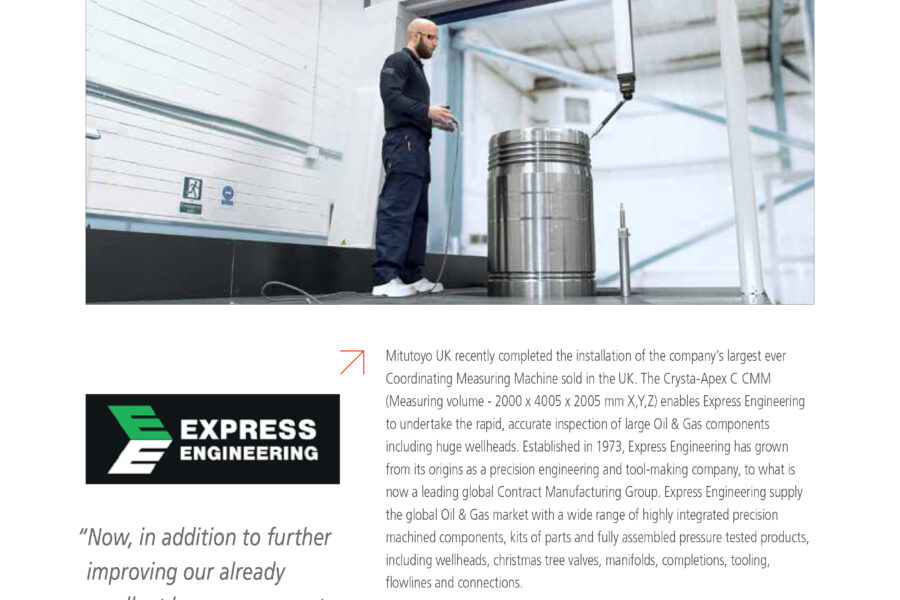

2020 marks the 40th anniversary of the establishment of the UK subsidiary of the Mitutoyo Group. From modest beginnings, Mitutoyo UK has grown to become the leading supplier of measuring equipment to British industry. To complement the company’s comprehensive metrology...

Following the hi-profile launch of Mitutoyo’s CRYSTA-Apex V range of CNC Coordinate Measuring Machines (CMMs), the Basildon, Essex based ESL Group recently became the first company in Europe to take delivery of one of the advanced CM Ms. Founded in...

Hertford based Qualiturn Products Ltd a perfect example of the productivity increases that can be achieved by the application of advanced IT systems, the use of high-yield machine tools and the adoption of cutting-edge automation technology. In addition to performing...

CNC Machining is what we do. We are Experts and on this channel we are bringing our knowledge and experience to YOU. Want more? Learn CAD, CAM & CNC Machining through our FREE TITANS of CNC: Academy.

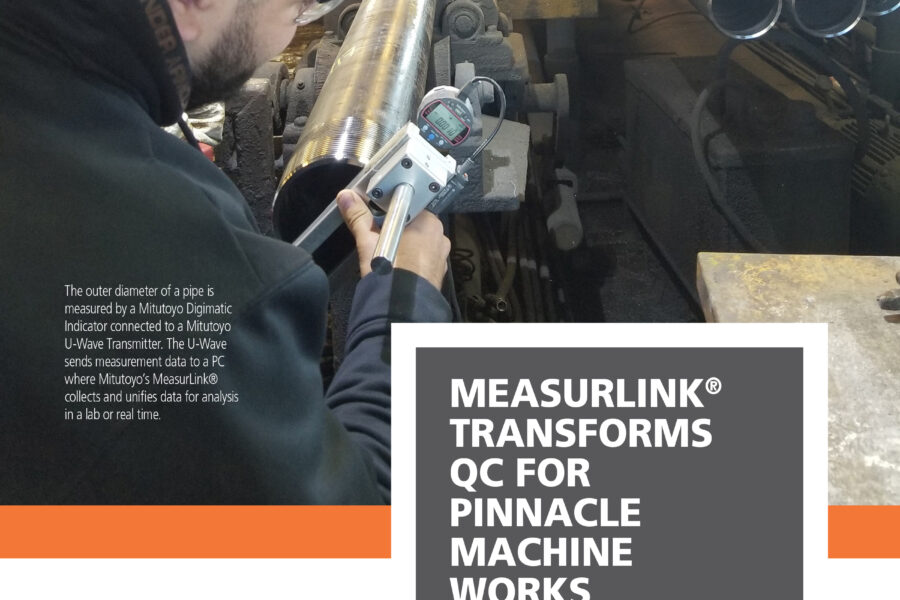

As Pinnacle grew, in late 2017 they embarked on a mission to transform and improve productivity. This involved a re-organization of the manufacturing plant, the rollout of lean initiatives and an investment in new tooling.

We go over how to use the Mitutoyo Optical Comparator along with the QM Data digital readout. Make sure to check out our other sites for more info! Facebook: https://www.facebook.com/DavistechCNC Website: www.Davistech.edu

Turning D2 Tool Steel on the ST-20Y! A friend needed some work done and fast, so we filmed the process. It gave us a chance to learn the machine and develop a workflow. We’ll cover the setup, how and why...

Mitutoyo Vision Measuring Systems represent the most comprehensive lineup of vision systems in the metrology industry. Our vision measuring systems include cutting edge capabilities such as 0.25 micron accuracy, sub-pixel automatic edge detection, tracking autofocus, unparalleled focus capability, speed and...

CNC Machining is what we do. We are Experts and on this channel we are bringing our knowledge and experience to YOU. Want more? Learn CAD, CAM & CNC Machining through our FREE TITANS of CNC: Academy.

Currently celebrating the 40th anniversary of its establishment, Mitutoyo UK has earned an excellent reputation for the accuracy and quality of its products and the wide range of metrology and testing disciplines it covers. Within the fields of contour and...

King’s Lynn based Merxin is a supplier of both generic and customized inhaler devices and has manufacturing capacity across the globe. Given the important tasks that Merxin’s products perform, quality permeates all aspects of the company’s activities. To enable its...

Today’s manufactured components are more complex than ever, with more parts diversity, more model year changes and tighter tolerances than ever before. This is driving a need for increased quality control and the implementation of Geometric Dimensioning and Tolerancing (GD&T)...

Getting In-Line: Challenges and Benefits of Embedded Measurement: A Quality Magazine Webinar. In-line/near-line metrology measurement provides the potential for fast, flexible, efficient inspection that increases throughput without compromising quality. Shop floor CMM measurement however carries unique challenges and requires a...

It’s an Honor to add Mitutoyo America Corporation to our list of Amazing Partners. Together we are building the largest FREE CNC Machining Education Platform in the World. CNC Machining is what we do. We are Experts and on this...

Height gages feature improved ease of operation and enhanced functionality.

First came smart people. They made machines. Over time, machines got smarter — and so did people. Today’s factory intelligence is the collaborative orchestration of people and machines. By blending intelligence from multiple sources, factories are truly becoming smarter. But...

In this Mitutoyo MeasurLink video, we learn how to configure derived characteristics for automatic averages and more. This is a great feature for data collection and statistical process control. For more information on MeasurLink 9 and to download an evaluation...

With a complete range of in-line and near-line coordinate measuring machines — including the all new Mitutoyo shop floor CMM – MiSTAR 555 Series — Mitutoyo delivers exceptional durability, speed and accuracy for factory-floor applications of nearly any shape, size...

In the mid1970s two enterprising friends decided to combine their joint passion for diving and their knowledge of precision-engineering. Working at first in an archetypical location that has spawned some of the world’s most successful business – a small domestic...

Based in Pendle in what has become known as Lancashire’s ‘Aerospace Valley’, Merc Aerospace is a renowned precision engineering company with over forty years of experience serving the aerospace industry. Specialising in the delivery of tight-tolerance components to demanding deadlines,...

Based in a purpose build 50,000 sq ft manufacturing facility in East Kilbride, Scotland, Quartztec Europe is the UK’s largest fabricator of quartz glass and one of the top five such companies in Europe. Quartztec Europe is a market leader...

Modern smart manufacturing brings with it greater efficiency, increased productivity, data quality — and new challenges for collecting and analyzing the data management process. How can you achieve absolute precision in both production and reporting? And ensure compliance with industry...

Introducing the new MiSTAR 555 shop floor CNC CMM from Mitutoyo. Versatility. Simple Operation. Reduced Footprint Compact Design. Best-in-class Drive Speed & Acceleration. Widest Temperature Accuracy Guarantee for a Shop Floor CMM machine. Exceptional Contamination Resistance. With the new MiSTAR...

Currock Engineering Co. Ltd. is a major supplier of total solution packages to the global Aerospace sector and to several other equally demanding industries. Established in 1963 as a sub-contract machining and general engineering business, by 1995 the urgent need...

Mitutoyo Sheet Metal Micrometers are used to measure the thickness of sheet metal, paper, plastic, and rubber parts where a deep throat micrometer is required.

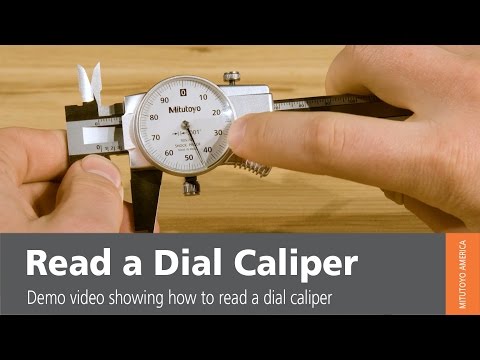

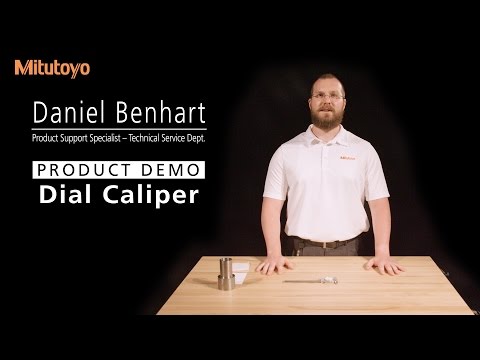

Mitutoyo America Corporation product demo video showing how to properly read a dial caliper.

Mitutoyo V-Anvil Micrometers are useful for measuring pitch diameters of taps which have a small diameter by using single-wire method. Measures the outside diameter of cutting heads with odd number of flutes such as taps, reamers and end mills.

The Disk Micrometer is designed to easily measure root tangent length of spur gears gears and measuring the thickness of sheet materials like paper, cardboard, rubber, and plastic.

The Mitutoyo Blade Micrometer’s anvil and the spindle have a blade for measuring the groove diameter of shafts, keyways, and other hard-to-reach areas.

Mitutoyo Caliper Type Micrometers have caliper type jaws making it easier to measure inside features with the accuracy of a micrometer.

The i-Checker is designed to calibrate a variety of indicators, including bore gages, Digimatic indicators, dial indicators, dial test indicators and linear gages.

Check Points for Measuring Instruments – This video covers the proper use of Digimatic Outside Micrometers from Mitutoyo.

Introducing our Gold Care Program. Simply, it’s the packaging of select industry-leading CNC CMM’s with productivity-enhancing products and services. Each setup is valued at over $15,000. And, it’s bundled at our base machine’s price, helping you to improve your total...

Mitutoyo’s vision product line represents the most comprehensive lineup of vision based metrology products in the world with cutting edge capabilities such as 0.25 micron accuracy, unique patented light adjustment tools, unparalleled focus capability, and new feature rich, easy to...

Mitutoyo America Corporation’s Lifting Lever installation instructional video.

In this video we discover how to use the Mitutoyo U-WAVE receiver as a virtual com port. The U-WAVE system enables easy wireless data collection from a measuring tool to a PC using the Digimatic protocol. Measurement workability is improved...

One of the newest features of Mitutoyo MeasurLink 9 is dynamic gauge which allows us to record readings from the gauge without actually taking them as a measurement value. MeasurLink 9 now allows for Max, Min and TIR data collection.

From precision gages to connection hardware and state-of-the-art software like MeasurLink® 9.0, Mitutoyo provides a full suite of precision metrology solutions for manufacturers. These solutions provide better smart factory integration, reliable wireless data collection and networked data management for faster...

Learn how to access the menu of a Mitutoyo MIG-4 measurement data transfer device, the multiplexer MIG-4USB and MIG-8USB convert digimatic data collection output measurements to ASCII text via USB or RS-232C and outputs it to an external data management...

In the automotive industry, disc brake calipers and ABS/Traction control systems are usually manufactured in large quantities, and in the past, it has been nearly impossible to capture data in real time. Real time data provides a streamlined process of...

The new U-Wave Fit wireless data management transmitter from Mitutoyo fits to the back of any Mitutoyo Digimatic hand-held metrology measuring instrument. This new design allows for a snug fit behind the display resulting in a more ergonomic feel for...

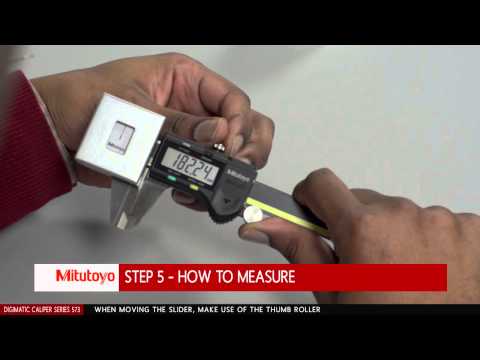

Mitutoyo product demo video showing the proper use of our digital calipers.

Our full range of roundness and cylindrical-form measuring instruments come with extensive analysis features that accommodates a wide variety of workpieces. Our PC based Roundtest products incorporate accessible Roundpak software with patented continuous internal/external diameter measurement reducing the need to...

The demand for fast and accurate inspection measurement continues to increase. Yet, achieving quality measurement programs takes time, and production cycles are often held up. To make matters worse, Different CMM programmers design model interpretations that influence or yield different...

Our Quick Vision ACTIVE Series CNC Vision Measuring System offers an automated vision measurement system featuring a space saving ergonomic design all while delivering high-speeds, high-accuracy and high-throughput.

From the lab to the field to the shop floor, see how Mitutoyo became the leading manufacturer of the most advanced metrology equipment in the world.

Ramcel Engineering Company (www.ramcel.com), located in Northbrook, IL, was founded in 1950 with the mission of providing precision, custom metal stamping, as well as contract mechanical assembly services, and robotic MIG & TIG welding services.

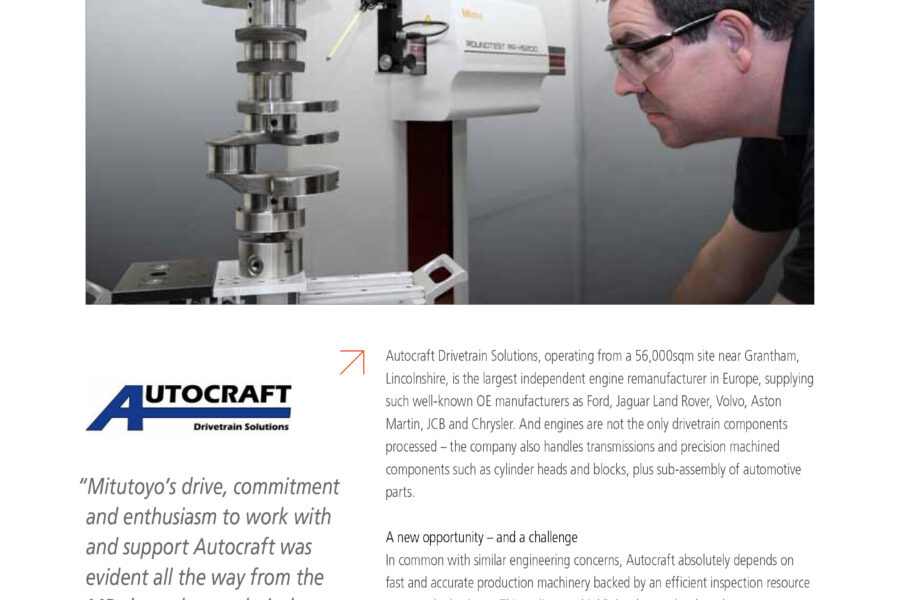

“In the remanufacturing business, you can take apart a transmission, clean it, replace all the soft parts and get it back to the customer when they need a new part,” said Gary Noel, chief operating officer and member of the...

With Mitutoyo Custom Solutions, you can customize Mitutoyo products and technology to meet the demanding needs of your specific application.

An educational guide to the basic technical information associated with a variety of Mitutoyo precision tools and instruments.

Outside micrometers are industry-standard measuring tools because of their high accuracy and resolution and ease of use.

A scant 500 thousand years ago, modern man (homosapiens) roamed the land. Today, their descendants use tools to build large structures, design high speed vehicles, and manufacture microscopic parts too small for the human eye to see.

Since the use of gauge blocks helps an organization to demonstrate traceability to national length standards, gauge blocks are in widespread use in corporations, universities, and laboratories throughout the world.

Mitutoyo America is also the first service organization to have A2LA Accredited Field Service Technicians. State-of-the-art M3 Solution Centers are geographically positioned to cover the United States.

It was during the 17th century when threads were utilised to measure the length of objects.

Mitutoyo’s unique ABS (Absolute) sensor automatically restores the last origin position when the indicator is turned on, allowing quickstart operation.

Simple, Easy-to-use Solar and Battery-powered Digimatic® Indicators.

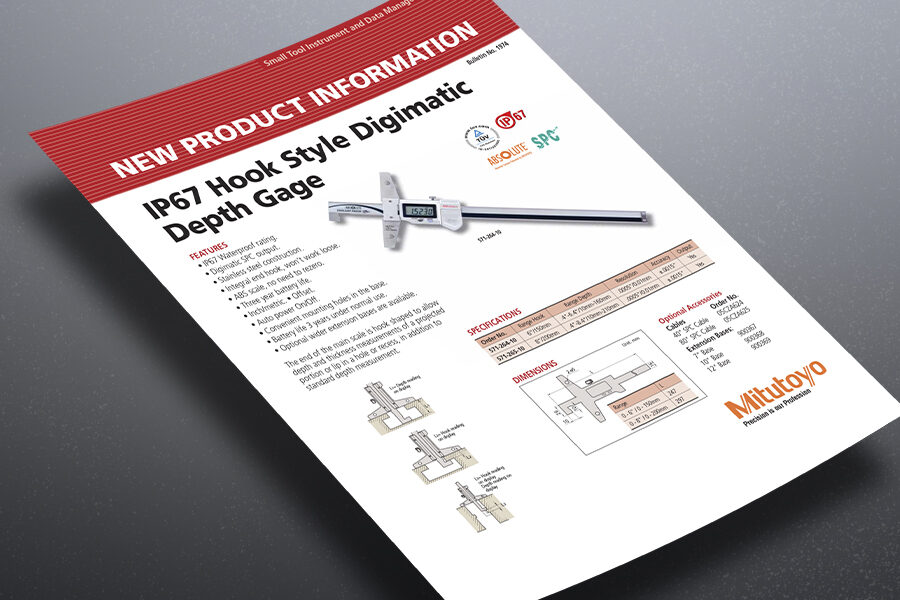

Specially designed to take depth and thickness measurements of a projection or lip in a hole or recess as well as standard depth measurements.

New model measures blind-hole diameter with high accuracy and high durability.

Best-selling range of bore gages now offers better accuracy, user-friendliness and durability.

New, high-precision thread machining technology has made it possible to create a new thimble design incorporating a highly accurate screw with a pitch of 0.1mm. This is one-fifth of the conventional micrometer pitch of 0.5mm and provides a feed of...

Delivering ±0.5 μm accuracy at 0.1 μm resolution means Mitutoyo’s MDH25MB is the most accurate hand-held micrometer available*, and this instrument will enable you to easily and rapidly measure workpieces that require very-high-accuracy measurement.

Twice as Long Battery Life as before and Drastic Improvement in Measurement Efficiency.

Equipped with the electromagnetic induction type absolute encoder and AOS (Advanced Onsite Sensor) applied for ABS coolant-proof calipers.

In addition to standard types of micrometers, Mitutoyo provides a wide variety of micrometers dedicated to measuring specific and special applications.

For Calculation, Peak-Value Hold and Bore Gage Applications.

The ability of the indicator to track small changes in displacement deteriorates with prolonged use due to minute changes in clearance between the gears.

ZERO CERA BLOCK can also improve calibration work efficiency by eliminating the need for temperature compensation leaving only the thermally induced dimensional change of the calibration target to be considered.

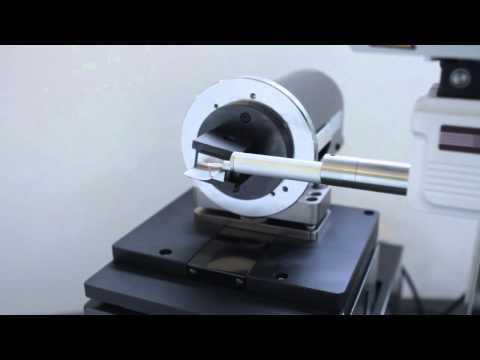

Roundness/Cylindricity Measuring System combines world-class accuracy with superior maneuverability/ analytical capability.

Offering the highest precision level in its class, exceptional ease-of-use, and multifunction analysis capability.

A new PC-Compliant Roundness and Cylindrical-Form Measuring Instrument with extensive analysis features to enable measurement of a wide variety of workpieces.

Compact roundness tester equipped with a wide range of analysis features and capable of accommodating a variety of workpieces.

A new PC-Compliant Roundness and Cylindrical-Form Measuring Instrument with extensive analysis features to enable measurement of a wide variety of workpieces.

Remarkable operability and functionality revolutionize contour measuring systems and enable measurement that is fast, accurate, and easy.

Mitutoyo offers a wide range of form measuring equipment to make accurate, reliable surface roughness, roundness and contour measurements for nearly any application.

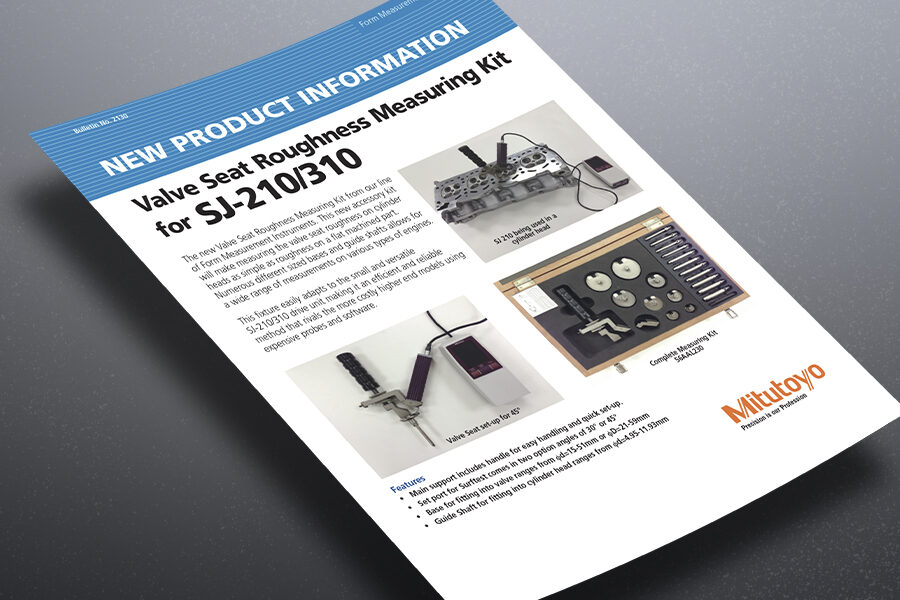

Numerous different sized bases and guide shafts allows for a wide range of measurements on various types of engines.

FORMTRACEPAK functions offer total support for measurement system control, surface roughness analysis, contour analysis, contour tolerancing, and inspection report creation.

Double performance in one system: combined contour and surface measurement machine delivers high accuracy, high speed, and simplified CNC measurement.

Surface roughness testers offer benchtop or portable operation and the choice of data analysis by PC or an easy-to-use dedicated processor.

The Surftest SJ-410 Series is a portable surface roughness measurement instrument with a user-friendly color-graphic LCD touch screen and takes measurements with the push of a single button.

The Surftest SJ-310 is a compact, portable, easy-to-use surface roughness measurement instrument equipped with extensive measurement and analysis features.

The CNC FORMTRACER SV-C4500 features a dual-sided stylus and performs highly accurate surface roughness and form/contour measurements with one unit.

The roughness profile (R-profile) is the profile resulting from electronic highpass filtering of the primary profile with a cut-off wavelength λ c.

Ideal for measuring the thickness or height of a workpiece that can be easily affected by the measuring force.

Durometers are suitable for testing natural rubber, neoprene, polyesters, P.V.C., leather, thiokol, nitril, rubber, wax, vinyl, cellulose acetates, glass, polystyrol, and other materials.

HH-411 is a compact portable hardness tester that is user-friendly. A single touch of a button performs the non-destructive impact hardness test so it’s extremely easy to test workpieces on site.

Unique electronic control makes the HR-530 series of hardness testers capable of Rockwell, Rockwell Superficial, Rockwell testing of plastics (A & B) and Light Force Brinell hardness testing.

The HM-200 series is ideal for quality control and mechanical characteristic evaluation using Vickers hardness testing of small areas.

The ergonomically designed FS70 high power microscope features extra long working distance plan objectives and is an ideal unit of a prober station for semiconductors.

Newly designed LED illuminators provide enhanced observation for higher accuracy and resolution.

Mitutoyo microscopes can be integrated into manufacturing systems, research and development equipment, and product inspection lines.

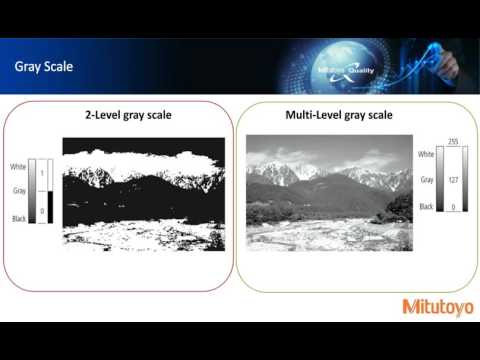

Optical data-processing system is what supports such a system configuration. In addition, “MeasurLink” offers the “Quality Control IoT that Mitutoyo advocates.”

The TAGLENS has ground-breaking ultra-deep focus, which allows completely in-focus images of the target to be captured instantaneously. This revolution in optical inspection will dramatically improve productivity and efficiency.

The LSM-6900 Series is an ultra-high accuracy non-contact laser-based measuring system mainly used for outside diameter measurements even on delicate or moving pieces.

Latest Generation of Absolute Assembly-Type Linear Scale. This scale leverages Mitutoyo’s unique electromagnetic induction technology to provide excellent resistance to oil, water, and other contaminants when compared with optical linear encoders.

This lightweight, easy to carry, straightness master is made of alumina ceramics, compared with conventional masters made from stone or iron.

The Mitutoyo MF and MF-U measuring microscopes are available in manual and motorized units. Each model is packed with features, functions and high magnifications for highly accurate measurements on miniscule-sized parts.

Mitutoyo Selectable Resolution LVDT Probes and Displays Adaptable to Customer Demands Suited to a Wide Application Range from the Inspection Room to Building into a Production Line.

With the broadest scope of any commercial lab in the country, we can calibrate any type of measuring device or dimensional artifact — from small tools to surface finish specimens, gage blocks and step gages, to cylindrical squares and roundness...

The ST700 Absolute Linear Scale uses features non-contact detection on exposed scales for precise linear positioning on a variety of different machine types.

Mitutoyo Digimatic Scales provides precise linear measurements and positioning. Digimatic Scale Units are available in horizontal and vertical mounting types for nearly any machine.

Highly accurate glass or metal-tape scales with ultra-compact detector head and an automatic signal-adjusting function for ease of installation.

The KA-200 Digital Counter shows displacements detected by linear scales. The KA-200 features high performance at a low cost with ABSOLUTE and incremental modes with 10 presets each.

The ABS AT1100 scale leverages Mitutoyo’s unique electromagnetic induction technology to provide excellent resistance to oil, water, and other contaminants when compared with optical linear encoders, thereby elevating the ABS AT1100 to the level of a highly reliable NC machine-tool...

The data logger function also allows storage of up to 1,000 pieces of data in memory, and batch transfer of stored data to an Excel-format inspection certificate, etc., by connecting to a PC with a USB cable.

The “U-WAVE” wireless communication system, collects measurement data in the inspection process swiftly and accurately, to increase a company’s competitiveness with detailed data analysis.

This document details how to select the right partner, hardware, and software needed to fit unique applications. Whether it is a single inspection station or a multiple facility installation, Mitutoyo offers the products and solutions to bring it all together.

MSURF has been updated to Version 5.0, making this dedicated point-cloud software for Mitutoyo’s SurfaceMeasure line-laser probe even more powerful by delivering productivity improvements to a wide range of applications. The software has various online/offline packages to provide the best...

By automatically adjusting the laser intensity and camera sensitivity for the environment and the workpiece material, the SurfaceMeasure achieves powderless measurement, providing a simpler laser-scanning environment.

By utilizing the technologies developed over the years on surface roughness measuring machines, our Coordinate Measuring Machines can now execute surface roughness analysis by implementing a Surftest Probe and the dedicated software.

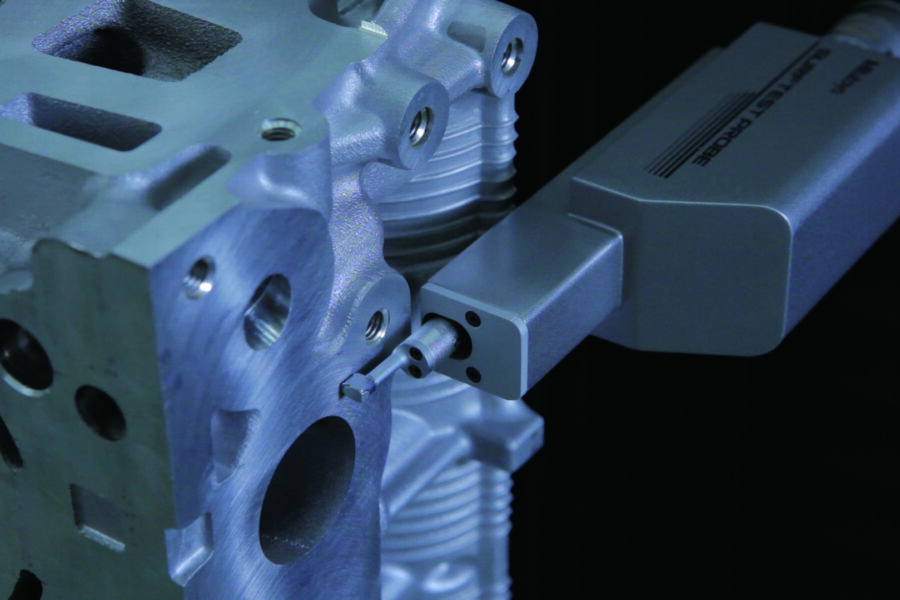

Mitutoyo offers many different CMM probe options, ranging from touch-trigger to non-contact probes as well as surftest probes and motorized probe heads to give manual and CNC CMMs more measurement versatility.

Based on our well-received standard coordinate measuring machine technology, we have developed, designed and manufactured coordinate measuring machines using various custom specifications in response to customer demands.

The automation of 3D coordinate measurement by introducing a CARB series system can allow simplification of conventional inspection/fixing jigs or even the elimination of inspection jigs and can achieve major cost reductions in addition to improving accuracy in parts and...

Production-line Coordinate Measuring System addressing today’s need for efficiency.

MiCAT Planner software by Mitutoyo generates CMM part programs with unprecedented efficiency. This drastically reduces programming efforts in developing part programs for coordinate measuring machines. The software’s automatic measuring program generator saves time while reducing costs.

High-performance, low-price CNC coordinate measuring machine meets global standards.

The CRYSTA-Apex EX Series has a 5-axis design that offers a choice of highly productive measurement methods, including “head touch” for point measurement by moving the probe head only in two axes, and high speed 5-axis touch trigger scanning.

The MACH Ko-ga-me is a fast, compact, lightweight, and easy-to-mount CMM and it is the ideal solution for automated cells. Mounted on any rigid frame, including machine tools, the MACH Ko-ga-me will provide CMM capabilities without the space requirements of...

SCANPAK provides high-performance scanning of work pieces and evaluation of profile callouts.

The CMM System Manager allows you to create a virtual representation of your CMM for simulation.

GEOPAK (Basic Geometry module) provides an easy graphical console to the operator by the use of toolbars and windows which can be personalized to the operator’s preference.

MCOSMOS allows integration among a series of applications, improving the efficiency of your CMM and the productivity of your quality control functions.

The Mitutoyo Styli and Accessories product line includes more than 600 probe components, as well as highly specialized equipment, to provide the best solution for your specific measurement needs.

Rather than acquiring manufacturing plant on a piecemeal basis, the practice of companies purchasing and using machine tools of various categories from single, preferred vendors is now firmly established. For example, milling machines of a particular brand would be used...

Over the past 40 years, Exeter, Devon based Rotamic Engineering Ltd has established an excellent reputation for the manufacturing of precision machined components. In addition to serving the demanding Defiance, Formula 1 and Medical industries, Rotamic has supplied customers in...

In this episode of the Metrology Training Lab , we’re going to revisit the calibration of calipers and look at a specific issue with dial caliper calibration.

Manufacturing companies across every industry want to improve the quality of their products while keeping their operating costs low. Mitutoyo’s MeasurLink is the ideal software to assist companies with achieving these goals. As a Data Collection and Statistical Process Control...

In episode #021 of Mitutoyo’s Tool Tip video series, we discover how to use the semi-float option of the LH-600 Digital Height Gauge. The semi-float feature allows for precision measurement of the height gauge while moving. This is a time...

In this episode, we’re going to discuss the calibration of the high accuracy Mitutoyo MDH outside digital micrometer. In past episodes, we’ve discussed the general calibration of outside micrometers, but the MDH is more than twice as accurate as any...

In this height gauge tutorial, we will look at setting up a new Mitutoyo Linear Height Gauge. We will cover the height gauge calibration procedure, zero the scale, set the absolute origin and switch from lower to upper probe positions.

In episode 012 of the Metrology Training Lab, we’ll explain the accuracy and micrometer calibration of mechanical outside micrometers. You may be surprised to find out the accuracy of a mechanical micrometer with a graduation of 0.001” is one-tenth of...

Learn 4 tips that will help make your Mitutoyo KA-200 digital readout more productive. The KA-200 Counter is a great DRO for machine shop Bridgeport or any other milling machine or lathe.

Here’s my review of my favorite measurement tool in my shop, Mitutoyo 6″ digital calipers (model number 500-196-30). Being able to get more reliable measurements is incredibly valuable if you care about precision. I procrastinated way too long on buying...

In episode 11 of the Metrology Training Lab, we look at the influence of temperature measurement in the quality lab. All materials grow and shrink as the temperature changes. You may think these changes are small, but every measurement is...

With a proud heritage that stretches back to 1885, Hatfield, Hertfordshire based Davall Gears is a long established UK manufacturer and supplier involved in the design and production of gearing systems and specialist gearboxes. In addition to serving a long...

Catch a glimpse of what the future of metrology looks like, and how Mitutoyo has set itself up to play a key, innovative role in it. Mitutoyo America’s President Matt Dye explains the quick evolution of smart factories and smarter...

Nothing in the manufacturing industry epitomizes human safety more than the name Martin Baker. Founded in 1929 as an aircraft manufacturer that evolved to aviation ejector seats, the main entrance to the Uxbridge Company’s Headquarters has a large screen with...

Tewkesbury, Gloucestershire based Bushell and Meadows Ltd is a renowned subcontract manufacturer of high-quality, precision engineering components. The business has invested heavily in state-of-the-art, high-speed CNC machine tools and serves a range of demanding markets including the medical, aerospace and...

We’ve been teaching hands-on classroom courses in dimensional calibration for decades and in recent years we’ve developed some written theory tests along with performance tests to demonstrate skills. This had led to Mitutoyo America issuing the first and only certified...

Based on a heritage site where Edwin Beard Budding invented the lawnmower in 1830 and the adjustable spanner in 1842, lmpcross Ltd is a manufacturer that continues this tradition; branding its business as a ‘world class centre of specialist precision...

Requirements for calibration appear in most national and international quality standards, and most organizations recognize that measuring equipment must be calibrated. However, there is much confusion regarding the definition of calibration, and this confusion increases quality-related risks to organizations. The...

This technical bulletin addresses how measurement accuracy and uncertainty can be accounted for when making statements of conformity to specified requirements (In/Out tolerances or Pass/Fail decisions.) In particular, this technical bulletin explores one simple rule called the simple acceptance and...

In this episode we are going to talk about some quality rules that are often used in calibration to determine the acceptability of measurement standards or systems. For example, in a past episode of the metrology training lab we discussed...

This technical bulletin addresses the accuracy and calibration of granite surface plates. The technical basis for this document is the American national standard (ANSI standard) entitled B89.3.7-2013, Granite Surface Plates. This technical bulletin summarizes key technical issues; however, the ASME...

In this episode, we want to recognize and appreciate a piece of measuring equipment that rarely get much glory but is the foundation for much of the work done in this business – the granite surface plate. The surface plate...

In today’s Tool Tip, we learn about the new Mitutoyo D2 Digimatic output system for SPC. The D2 system is compatible with U-Wave and MDH Micrometer from Mitutoyo.

In this episode of the Metrology Training Lab series by Mitutoyo, we learn how to calibrate gage blocks, stacking or wringing gauge blocks and a brief history. These simple little blocks are something special. Each one with their flat and...

This technical bulletin addresses the accuracy and calibration of digital, dial, and vernier calipers. The technical basis for this document is the American national standard (ANSI standard) entitled ASME B89.1.14-2018. This technical bulletin summarizes the most important technical issues; however,...

In this episode, we’re going to talk about the how to calibrate calipers. In past Mitutoyo Metrology Training Lab episodes, we have defined the concept of calibration, discussed the purpose of calibration, and introduced important aspects of what makes a...

In today’s Tool Tip we look at the Mitutoyo Height Gage LH-600E and discover how easy it is to perform data output. The Linear Height LH-600E/EG Series 518 is a high performance 2D measurement system for use in calibration and...

In Episode 6 of the Mitutoyo Metrology Training Lab series, we look at how to calibrate outside micrometers. Calibration is a search for errors and we want to develop a calibration method that efficiently hunts down and finds any potential...

When it comes to Mitutoyo’s second generation of Test Indicators, there really is no comparison, and Mitutoyo’s small tools product support specialist, Mike Grosenbach, demonstrates four reasons why the new Mitutoyo Dial Test Indicators are the best in the metrology...

In this metrology training episode, we are going to teach you how to speak like a measurement professional. We are often dealing with small numbers in this business – tolerances – errors – deviations – uncertainties – most of the...

Mitutoyo Tool Tip Episode #015, learn how to capture the screen from the SJ-210 Surface Roughness Tester. The Surftest SJ-210- Series 178-Portable Surface Roughness Measurement Tester features a 2.4-inch color graphic LCD provides excellent readability and an intuitive display that...

In this episode of the Metrology Training Lab where we demonstrate how to calibrate, we are going to talk about requirements traceability, or sometimes called metrological traceability. Here’s the question that traceability and calibration answers – say I make a...

Now part of Littelfuse, Chippenham based IXYS UK Westcode Ltd has been at the forefront of power semiconductor design since the early part of the 20thCentury. With origins in the mid 1920’s, Westcode Semiconductors began life as part of the...

In this week’s Tool Tip, we look at the free surface finish measurement software from Mitutoyo. The Surftest SJ-201P, 210, 301, 310, 401, 402, 411, 412, 500, SV-2100 Metrology Communication program is a free surface roughness measurement software package. Please...

The Ford Engineering Group is an award winning, family owned corporation specialising in the machining and pressing of components and assemblies for the aerospace, automotive and related high-technology industries. The Group, that can trace its origins back to 1910, is...

In episode 003 of the Metrology Training Lab, Dr. Jim Salsbury examines what makes a good calibration method. We look at five calibration methods developed by the American Society of Mechanical Engineers or ASME. The American National Standards covered in...

In this unboxing video, we look at the Mitutoyo 500-762-20 Digimatic Caliper the 6 inch coolant proof caliper. Features include IP67 Waterproof rating, hardened stainless steel construction, OD, ID, depth and step measurements, SPC output and fitted case.

Mitutoyo Tool Tip 013 Skidded VS Skidless – In this episode of Mitutoyo’s Tool Tip, we look at the difference between skidded and skidless surface roughness measurement. Surface roughness measurement or surface finish, can be measured using various metrology roughness...

In the second video of our Metrology Training Lab series, we continue our calibration training and address the following questions. 1. What does calibration mean? 2. What is the real purpose of calibration? 3. What makes a bunch of measurements...

Learn how to install the Mitutoyo wireless U-WAVE receiver for SPC data collection. This video is part of a series designed to be an installation and instruction guide for MeasurLink® SPC software and the Mitutoyo U-WAVE quality control wireless system....

Monitor Coatings Limited is a privately owned company with over 30 years of experience in providing high quality coatings to a wide range of demanding industries, including the Aerospace, Oil & Gas exploration and Steel sectors. Monitor applies its unique...

Over recent years, a wide range of advanced machine tools have been developed to help satisfy the global aerospace manufacturing industry’s requirement to produce parts faster than ever before. Although these innovative machines manufacture complex components within much faster cycle...

Now regarded as one of the UK’s leading subcontract engineering business, it is difficult to believe that North Shields based, Chirton Engineering Ltd was established as recently as 2003. From relatively modest beginnings, the company has enjoyed a meteoric rise...

Precision Moulds & Tools Services Ltd was formed in 1991 by two partners who shared a passion for high-precision machining and a vision of the future of high quality tool making. Over the past 25 years the company’s founders have...

Established in 1968 the Precision Machinery division of Kawasaki has been at the forefront of hydraulic technology and development for nearly 50 years. The Kawasaki brand is synonymous with quality and innovation in hydraulic pumps, motors, valves and complete systems...

Since the 1920’s the Cross Manufacturing Company has specialized in the design and manufacture of heat resisting wrought alloy sealing rings and associated products. Cross’ expertise within its chosen fields has resulted in the company becoming a leading supplier to...

Few companies involved in the manufacture of aero engine components can boast a heritage that stretches back to the dawn of the jet engine age. One such concern is JJ Churchill. Founded by Walter Churchill on Christmas Day 1937, Churchill...

There comes a time when older inspection equipment gets to the stage where its performance threatens to create a bottleneck in production. This was the situation reached with a 10-year-old Vision Measuring System at Johnson Matthey Fuel Cells (JMFC) in...

When you operate at the cutting edge of your field with customers absolutely relying on you to come through with solutions, on time and every time, issues that affect production quality in engineering or manufacturing must be stamped on without...

Part of Castings PLC, CNC Speedwell is a large volume manufacturer of high specification automotive components. Approximately 400 people work at the groups’ casting foundry, whilst CNC Speedwell, which is located opposite the foundry in Brownhills, West Midlands, employs a...

Since STOBA Prazisionstechnik’s formation in Southern Germany more than 50 years ago the company has grown into a multinational concern, currently employing some 650 workers in four high-tech manufacturing plants located in southern Germany; Yantai in China and Small Dole,...

Easy data management using the wireless Mitutoyo U-WAVE system. First, connect the U-WARE receiver to the PC, launch the U-WAVEPAK software, open your data collection software such as Microsoft Excel or other statistical process control software and finally start taking...

Learn how Mitutoyo MeasurLink works with DAQ sources. Use MeasurLink for data collection from USB wired and U-Wave wireless systems. Connect up to 1,600 metrology devices for SPC (statistical process control) using the U-Wave transmitter and receiver to PC software...

This week we find out what’s in the 543-342B Digimatic indicator box. The Mitutoyo 543-342B Digimatic indicators are for calculation applications. These metrology indicators allow the user to enter the appropriate formula factors for a fixture to the application. This...

Mitutoyo Type A & Type B SPC cables are used to output measurement data from IP67 digital calipers or micrometers with statistical process control output feature to the digimatic mini processor, digimatic display unit, multiplexer or other device. SPC Connecting...

In this video, we will demonstrate how to unpair the Mitutoyo U-WAVE Data Management Receiver. The U-WAVE SPC system enables easy wireless metrology data communication from a measuring tool to a PC using the Digimatic statistical process control protocol. Measurement...

Leeds, West Yorkshire based FTL Technology is one the UK’s leading suppliers of precision engineered seal solutions. In addition to offering a broad range of consultancy, design and seal manufacturing services, the company also has access to a wide range...

Mitutoyo Unboxed Friday 005 – This week we look at the Mitutoyo MDH Micrometer and find out what’s in the box. The Mitutoyo 293-130-10 MDH High-Accuracy Sub-Micron Micrometer, as seen on Quality Digest, has a measuring range of 0-1″/0-25.4mm inch/metric.The...

This week we look at ways to reduce the misuse of your Digimatic® indicators. Learn how to lock out the inch/metric, TIR, min/max, preset and zero functions on Mitutoyo ID-C Indicators. ID-C Parameter Setting Software: https://www.mitutoyo.com/idcsoftware

The Mitutoyo 293‑180‑30 QuantuMike is a coolant proof micrometer that features a rapid measurement due to the 2mm of spindle feed for every thimble revolution. The patented ratchet thimble mechanism* helps ensure repeatable results by transmitting microvibrations along the spindle...

When connected to a PC’s USB port, the Mitutoyo USB SPC data collection Input Tool is automatically recognized as an HID (Human Interface Device) keyboard device – a standard Windows® driver. No special software is required for data management. A...

The 4 piece Mitutoyo Machinist Caliper and Micrometer Tool Kit (64PKA070A) is examined in this week’s unboxing video. This machinist tools kit contains the following items: • 101-117-Outside Micrometer (Friction Thimble Type) (Range: 0–1”, Graduation: .0001”) • 129-132-Depth Micrometer (with...

In this episode of Tool Tip, we discover how to send detailed traceability information from MCOSMOS to MeasurLink Real-Time Software using Structured Sublot.

This week we see what’s inside the Mitutoyo SERIES 568 – ABSOLUTE Digimatic Bore Gage Kit.

The EC-100 Digimatic SPC display can be connected to Mitutoyo devices with Digimatic output, including micrometers, indicators, calipers and LGS/LGD Linear Gage to assist with statistical process control.

Looking for the Mitutoyo 513‑402‑10T Dial Test Indicator? Check out this full unboxing video.

MeasurLink Sales Specialist Jeremy Banks demonstrates how to use channel mapping in MeasurLink. Mitutoyo’s MeasurLink 8 Real-Time Professional Edition enables customers to connect and acquire data from Mitutoyo Coordinate Measuring Machines, Vision and Form Measuring Systems via native integration (DDE).

In this video we show how to use a dial bore gauge, telescoping gages, digital bore gauges, digital indicator bore gage and the Mitutoyo Borematic to accurately measure a cylinder bore, taper and out-of-round. Learn about Measuring an Engine Cylinder...

The U-WAVE system enables easy wireless data collection from a measuring tool to a PC using the Digimatic protocol. Measurement efficiency is improved by eliminating the long and cumbersome data management cables. The user-friendly interface allows data to be loaded...

What to know how to calibrate your metrology tools? In this episode of Metrology Training Lab, we discuss Calibration, which is critical to maintaining the quality and accuracy of your measuring equipment and what it means to calibrate your tools.

The DP-1VA allows for SPC data collection from a Digimatic gage. This metrology data can be stored in the device, sent to a software like Excel, IT-Pak or data logging software such as MeasurLink, and printed. In this video, we...

Mitutoyo America Corp. (Aurora, IL) brought one of its brand new HR-530 series Rockwell hardness testers to Advanced Design & Manufacturing (ADM) Expo, which was held in Cleveland on March 7 and 8, 2018. The series features a unique electronic...

Almost ten years ago, JCB Chief Executive Officer Lord Anthony Bamford had a vision for educating the next generation of engineers. This inspirational spark led to the globally renowned yellow goods manufacturer establishing The JCB Academy in 2010.

Ranked as one of the world’s top 100 new universities in the respected ‘Times Higher Education Rankings 2017’, Portsmouth University has rapidly ascended the UK academic rankings. This is credit to an £150m+ investment over the last ten years in...

Machining Two Gears for our own good! Rubber slats in the doorway work great to keep the office and shop isolated; however, getting slapped in the face countless times a day wasn’t part of the plan. So, let’s machine these...

With operations in 26 countries and commercial offices in over 35 countries, Tata Steel is one of the world’s most geographically diversified steel producers. Tata Steel serves a wide variety of demanding global markets and is a leading manufacturer of...

Taking its distinctive name from the initials of the company’s three founders surnames, O.L.D. Engineering was established in 1971 in a small factory in Sharnford, Leicestershire. The fledgling subcontract business soon earned a reputation for delivering work on time and...

Widely recognised as the world leader in the design and manufacture of transmission and drive train technology, Xtrac has built its business and reputation on a passion for innovation, precision and quality. So, when the company needed a metrology supplier...

Based in the Aerospace Park at Prestwick Airport, Ayrshire, Scotland, Precision Tooling Services (PTS) provide an extensive range of first-class machining and manufacturing services to a wide variety of demanding sectors, including the Aerospace, Automotive, Renewables and Oil & Gas...

What happens to solar powered calipers and indicators from Mitutoyo during a total eclipse? We traveled to Southern Illinois to see if our solar powered tools continue to work during the Great American Solar Eclipse.

Recovering from a devastating discovering: a rusted surface grinder table. Follow along as we wire wheel, scrap, grind, clean and adjust to get the Okamoto Surface Grinder back in good working order. Finally, checking the results with a 5-block test!

After a Richard King hand scraping class, I wanted to check our set of V blocks to see how accurate they are – so let’s discuss different metrology and measuring techniques to measure angles.

Welcome to Quality Digest’s new show, “How To,” a series for quality control and quality assurance specialists who need quick instructions on how to get things done. Featuring Quality Digest’s editor in chief Dirk Dusharme and Craig Howell, president of...

Welcome to Quality Digest’s new show, “How To,” a series for quality control and quality assurance specialists who need quick instructions on how to get things done. Featuring Quality Digest’s editor in chief Dirk Dusharme and Craig Howell, president of...

Welcome to Quality Digest’s new show, “How To,” a series for quality control and quality assurance specialists who need quick instructions on how to get things done. Featuring Quality Digest’s editor in chief Dirk Dusharme and Craig Howell, president of...

Welcome to Quality Digest’s new show, “How To,” a series for quality control and quality assurance specialists who need quick instructions on how to get things done. Featuring Quality Digest’s editor in chief Dirk Dusharme and Craig Howell, president of...

Welcome to Quality Digest’s new show, “How To,” a series for quality control and quality assurance specialists who need quick instructions on how to get things done. Featuring Quality Digest’s editor in chief Dirk Dusharme and Craig Howell, president of...