Plastics are an integral part of modern manufacturing—and a complex case when it comes to metrology. Mitutoyo optical and low-force dimensional measurement solutions are ideal for soft materials and high-volume production. When you need to maintain the ultimate level of accuracy and repeatability using injection or die molds, Mitutoyo solutions get the job done.

Plastics Industry Realities

Manufacturing plastics involves dealing with mutable, yielding material that can be easily warped or damaged by conventional tactile metrology. What’s more, inaccurate pieces can lead to increased costs for material disposal and recycling. This makes it even more important for plastics manufacturers to hit their tolerances every time.

High Volume

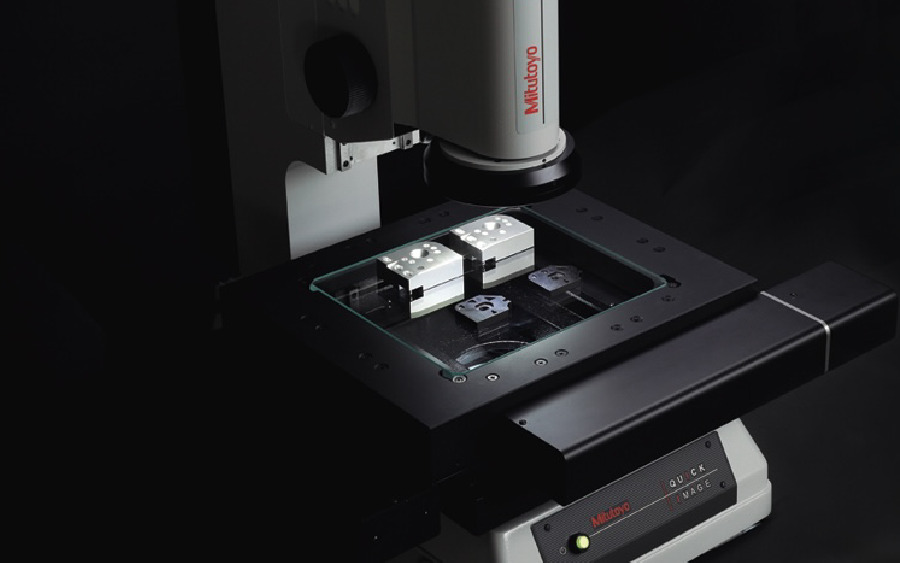

The same die or injection mold can be used to produce thousands or millions of identical components. That means the smallest imperfection in a mold can cause millions of repeated errors, rendering huge quantities of material useless. Quality assurance testing is essential, but testing each individual component can slow down production. Mitutoyo offers several different solutions for this including contact-less CMMs and Vision Measuring Systems.

Complex Measurements

Edge-to-edge dimensions, surface testing, z-axis height measurements, hardness testing: the list of possible metrology applications needed for a single plastic component is a long one. A range of non-contact or low-force solutions are needed to confirm all these factors are in compliance without causing damage to the part itself. This is where the comprehensive lineup of Mitutoyo metrology instruments, tools and equipment provides companies a great advantage.

Mitutoyo’s Expertise

Mitutoyo understands that not all metrology solutions are suited to the unique requirements of plastics manufacturing. We produce instruments designed to take the most accurate measurements possible without causing any damage to the workpiece itself.

“Low-Force” solutions with adjustable load pressure

Hardness testers and durometers suitable for a range of hardnesses, even soft foams

Optical gauging solutions in a full range of sizes and resolutions

Plastics Metrology Solutions by Mitutoyo

Capable of both contact and non-contact measurement, our CMM solutions are ideal for 3D inspection

Easily manage your measurement data using a Mitutoyo data management system powered by MeasurLink® software

As an industry-leading provider of contact and non-contact sensor systems, Mitutoyo supports your strictest measurement needs

Mitutoyo builds a wide array of highly accurate, best-in-class vision systems for non-contact measurement applications

Enhancing Accuracy and Productivity for Rubber Manufacturing

Roembke Manufacturing & Design enables the high-precision molding of rubber materials, which makes flash control and efficiency essential. Find out how a CMM solution from Mitutoyo helped Roembke speed up their run time by 86 percent.

The Quality Show is an event by Quality that will help connect manufacturing professionals with a growing network of top-tier suppliers and cutting-edge subject matter experts on an array of topics. As the region continues to see massive investments in...

Come find us at Booth #1100 at RAPID + TCT 2026! Here we will be showing off our inspection equipment and metrology solutions.

Join Mitutoyo at “Aviation’s Season Opener” from April 14–19, 2026, in Lakeland, Florida. As the world of aerospace demands absolute accuracy, we’re bringing our latest precision metrology solutions to the 52nd Annual SUN ‘n FUN Aerospace Expo. Visit us in...

Don’t miss the chance to visit our Mitutoyo booth at MRO Americas 2026! From cutting-edge metrology tools to innovative software solutions, we’ve got everything you need to stay ahead of the curve. Join us at MRO Americas and see how...