Whether it’s oil and gas or renewables, consistent energy production depends on reliable machinery and infrastructure. Dimensional measurement and statistical analysis solutions from Mitutoyo help overcome environmental and inspection challenges, bringing improved precision and performance to energy applications.

Energy Industry Challenges

The world’s demand for energy never slows, which makes it essential for mechanical and infrastructure applications to deliver sustainable, reliable, ongoing performance. What’s more, as new regulatory requirements come into play, data collection is essential to the traceability process.

Hazardous Environments

From extreme temperatures to harsh weather and high pressure, energy solutions must meet strict industry codes and standards while continuing to perform in even the harshest conditions. Additionally, maintenance can pose its own challenges, requiring top-of-the-line field service for large or unwieldy machinery.

Minimal Downtime

In order to meet steadily rising end-user needs, energy equipment must increase operational cycles while steadily improving efficiency. This makes accuracy of the utmost importance, since any unplanned downtime can disrupt an entire population’s energy supply.

Mitutoyo’s Expertise

Dependable energy production requires the most reliable metrology solutions available. Armed with Mitutoyo’s versatile portfolio of metrology solutions and ISO/IEC 17025 accredited calibration services, you can ensure the quality and accuracy of your components in the lab, the production plant and in the field.

ISO/IEC 17025 accredited calibration services for equipment of all types

Trusted dimensional measurement accuracy for even the most complex components

Advanced measuring solutions suited for harsh measuring environments

Portable wireless data collection for in-process and on-location data capture

Energy Metrology Solutions by Mitutoyo

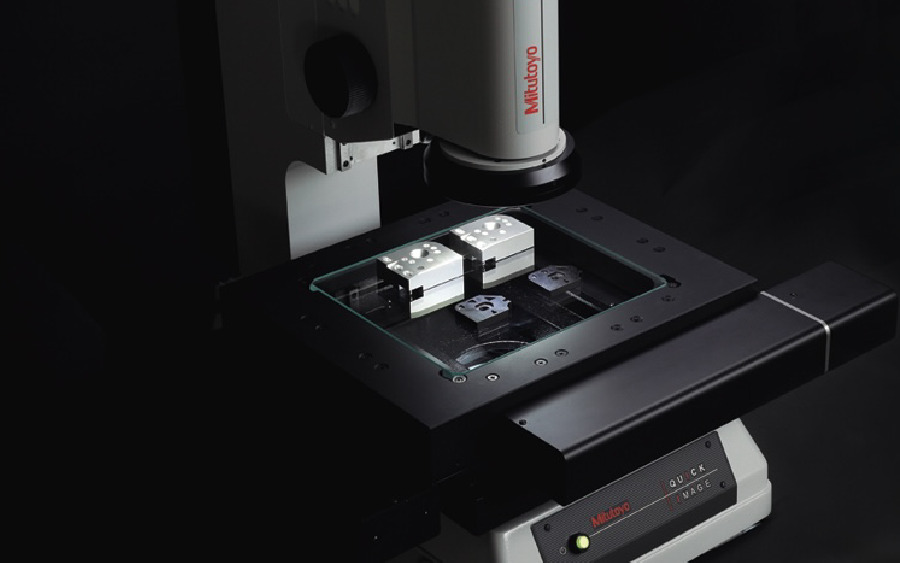

Capable of both contact and non-contact measurement, our CMM solutions are ideal for 3D inspection

Our form measuring solutions accurately assess complex geometries of any shape, roundness or roughness

Easily manage your measurement data using a Mitutoyo data management system powered by MeasurLink® software

Mitutoyo builds a wide array of highly accurate, best-in-class vision systems for non-contact measurement applications

Inspecting for Quality in Record Time

The global oil and gas industry depends on the precision machined components produced at Express Engineering. See how Mitutoyo’s rapid, accurate CMM solution — the UK’s largest — helped them accurately inspect wellheads in one-third of the time.

The Quality Show is an event by Quality that will help connect manufacturing professionals with a growing network of top-tier suppliers and cutting-edge subject matter experts on an array of topics. As the region continues to see massive investments in...

Come find us at Booth #1100 at RAPID + TCT 2026! Here we will be showing off our inspection equipment and metrology solutions.

Join Mitutoyo at “Aviation’s Season Opener” from April 14–19, 2026, in Lakeland, Florida. As the world of aerospace demands absolute accuracy, we’re bringing our latest precision metrology solutions to the 52nd Annual SUN ‘n FUN Aerospace Expo. Visit us in...

Don’t miss the chance to visit our Mitutoyo booth at MRO Americas 2026! From cutting-edge metrology tools to innovative software solutions, we’ve got everything you need to stay ahead of the curve. Join us at MRO Americas and see how...