Few industries have stricter quality control requirements than defense manufacturers. Rigorous traceability and calibration are essential in order to keep mission-critical applications in line with strict requirements. Mitutoyo has set the standards in metrology performance for decades, and we’re ready to bring that expertise to your military applications.

Defense Industry Realities

Accurate production of defense applications, both mechanical and electronic, is life-critical. Not only are military operators at risk, but so is the success of the entire mission. Meeting stated standards for production quality and safety is a major challenge, but failing to do so can’t be an option.

Strict Governmental Standards

Defense manufacturers have no shortage of documented standards to adhere to: ISO 9001, AS9100 and its derivatives, ITAR and more. The most accurate and reliable defense metrology solutions are needed to make sure that each component is fully in compliance.

Budgetary Restrictions

Strict budgets are nothing new to defense manufacturers, but that doesn’t mean standards can be allowed to slip. Manufacturers face a tough challenge: maintaining the highest level of accuracy, while still producing quickly, efficiently and at a lower overall cost.

Mitutoyo’s Expertise

Mitutoyo has been setting the standard in traceability and calibration for decades. From rigorous traceability processes to accredited calibration services, we deliver the accuracy the defense industry needs to maintain compliance.

NIST traceability to support standards-driven metrology processes

Seamless integration of hardware and software with standards-based quality

Industry-leading solutions for measuring advanced or composite materials and complex products

Defense Metrology Solutions by Mitutoyo

Capable of both contact and non-contact measurement, our CMM solutions are ideal for 3D inspection

Our form measuring solutions accurately assess complex geometries of any shape, roundness or roughness

Easily manage your measurement data using a Mitutoyo data management system powered by MeasurLink® software

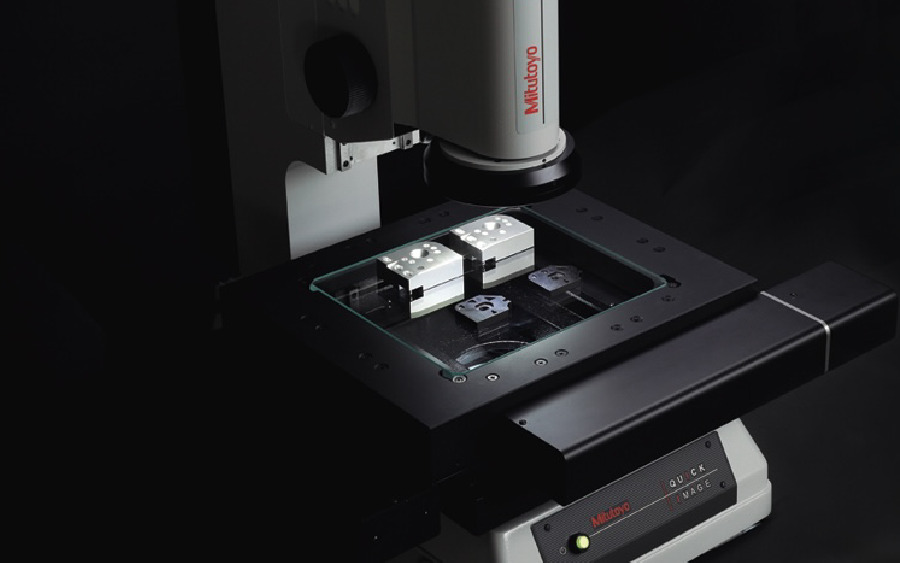

Mitutoyo builds a wide array of highly accurate, best-in-class vision systems for non-contact measurement applications

Our high-resolution microscopes and profile projectors measure minuscule electronic components with high accuracy and repeatability

As an industry-leading provider of contact and non-contact sensor systems, Mitutoyo supports your strictest measurement needs

Our accurate, user-friendly testing equipment solutions set the industry benchmark for most standardized testing methods

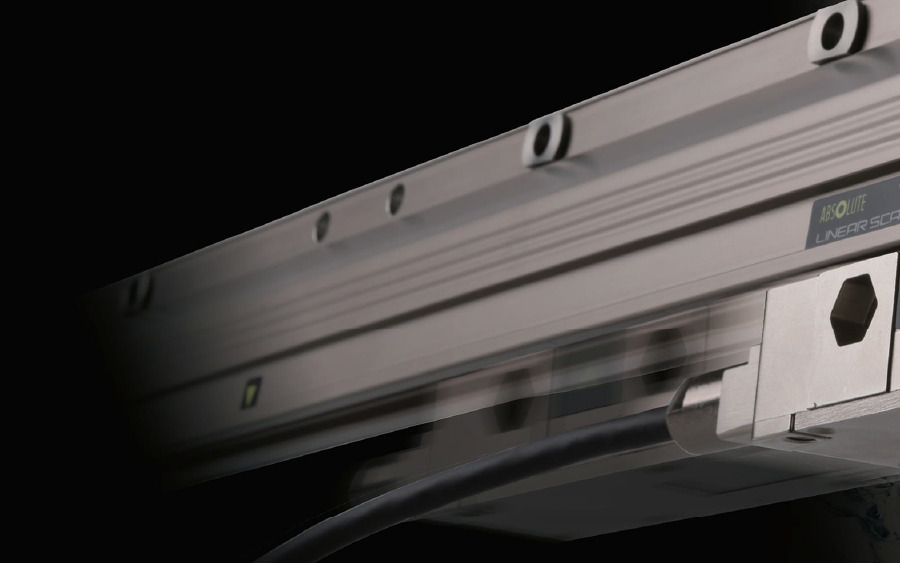

Mitutoyo digital and linear measurement tools deliver ultimate precision, accuracy to in-house machine tool applications and manufacturing

Flexible, Efficient Measurement for Defense Gages

The Naval Surface Warfare Center produces interface gages that certify weapon interchangeability on field devices and deployed ships, which means accuracy is absolutely essential. See how a flexible, ultra-precise CMM solution from Mitutoyo helped improve productivity and precision, while lowering costs by 40 percent.

The Quality Show is an event by Quality that will help connect manufacturing professionals with a growing network of top-tier suppliers and cutting-edge subject matter experts on an array of topics. As the region continues to see massive investments in...

Come find us at Booth #1100 at RAPID + TCT 2026! Here we will be showing off our inspection equipment and metrology solutions.

Join Mitutoyo at “Aviation’s Season Opener” from April 14–19, 2026, in Lakeland, Florida. As the world of aerospace demands absolute accuracy, we’re bringing our latest precision metrology solutions to the 52nd Annual SUN ‘n FUN Aerospace Expo. Visit us in...

Don’t miss the chance to visit our Mitutoyo booth at MRO Americas 2026! From cutting-edge metrology tools to innovative software solutions, we’ve got everything you need to stay ahead of the curve. Join us at MRO Americas and see how...