For the aerospace industry, extreme precision for the vast array of parts and massive assemblies is essential—but can be hard to achieve. At Mitutoyo, our measurement systems with advanced sensing capabilities bring unmatched accuracy to aerospace component measurement, improving verification and traceability.

Aerospace Industry Realities

The complex and varied nature of aerospace assemblies means that an ineffective measurement process will slow production time and compromise accuracy. Given the critical nature of aerospace manufacturing, less-than-perfect performance simply isn’t an option. The norm is 100 percent inspection and electronic data collection, and metrology solutions must be able to keep pace.

Complex Components

In aerospace applications, the requirements for accurate assemblies are strict. Every element in an engine or turbine must meet precise tolerances to ensure reliability. This goes beyond dimensional measurement—proper hardness, contour and surface roughness must be verified as well.

Time and Cost Restrictions

As regulatory requirements become stricter and production cycles become shorter, the aerospace industry must find ways to validate designs ahead of final assembly. Engineers rely on metrology techniques such as 3D modeling or with CAD comparison to prevent expensive rework and speed final production without compromising accuracy.

Mitutoyo and Aerospace

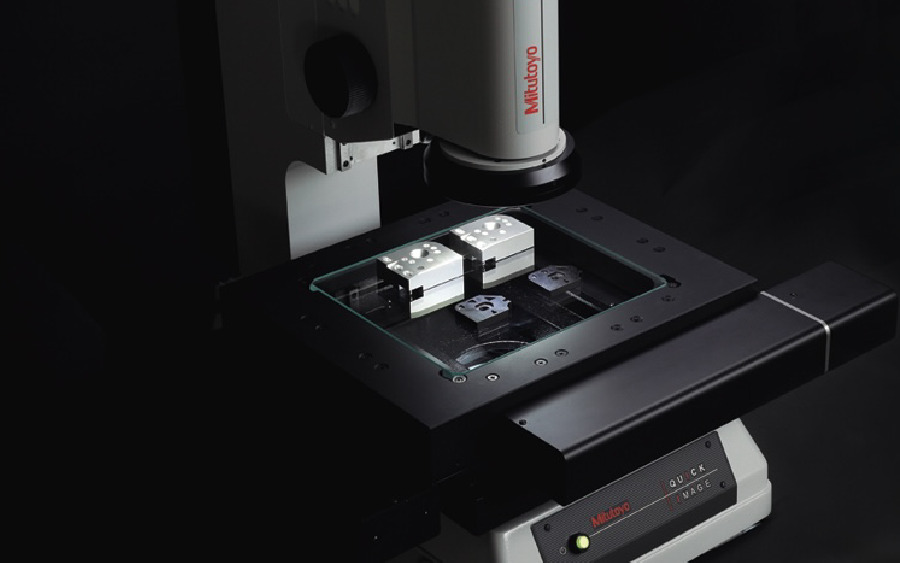

With best-in-class solutions for tactile, optical and form measurement, Mitutoyo helps the aerospace industry achieve reliability and traceability in every component.

Accurate 3D measurement using CMMs, Form or Vision machines

Traceable standards to ensure quality from components around the world

Intuitive MeasurLink ® Data Management Software to compile and analyze data accurately

Aerospace Measuring Instruments by Mitutoyo

Capable of both contact and non-contact measurement, our CMM solutions are ideal for 3D inspection

Our form measuring solutions accurately assess complex geometries of any shape, roundness or roughness

Easily manage your measurement data using a Mitutoyo data management system powered by MeasurLink® software

Mitutoyo builds a wide array of highly accurate, best-in-class vision systems for non-contact measurement applications

Bringing Precision to Powerful Aerospace Engines

ITP Engines recognized the need for advanced quality control equipment to increase production of aero-engine components without causing bottlenecks. See how a custom-integrated solution from Mitutoyo helped enhance precision and streamline throughput.

The Quality Show is an event by Quality that will help connect manufacturing professionals with a growing network of top-tier suppliers and cutting-edge subject matter experts on an array of topics. As the region continues to see massive investments in...

Come find us at Booth #1100 at RAPID + TCT 2026! Here we will be showing off our inspection equipment and metrology solutions.

Join Mitutoyo at “Aviation’s Season Opener” from April 14–19, 2026, in Lakeland, Florida. As the world of aerospace demands absolute accuracy, we’re bringing our latest precision metrology solutions to the 52nd Annual SUN ‘n FUN Aerospace Expo. Visit us in...

Don’t miss the chance to visit our Mitutoyo booth at MRO Americas 2026! From cutting-edge metrology tools to innovative software solutions, we’ve got everything you need to stay ahead of the curve. Join us at MRO Americas and see how...