Automated drug delivery devices, robotic surgery, and microscale and nanoscale devices make new medical advancements possible, but they also require levels of precision measurement approaching and even meeting 100% accuracy. With our extensively tested metrology devices and proven track record of precision, Mitutoyo is helping to move medical technology into uncharted applications.

Medical Industry Realities

Despite facing unique challenges and stringent regulations, medical technology manufacturers must be able to produce life/health-critical devices with incredible precision.

New Metrology Processes

As robotics and automated technology change the medical landscape, new metrology instruments are needed to keep these complex applications accurate. That's why companies around the world come to Mitutoyo as we have the best, most trusted and innovative metrology solutions necessary to ensure accuracy for medical device production and applications.

Complex Requirements

Medical technology devices must adhere to strict hygiene, safety and performance standards, all while meeting stated tolerances for dimensional measurement. Without the proper metrology solutions, manufacturers may struggle to meet these requirements, particularly when working with challenging material, which is why the broad range of Mitutoyo high-accuracy metrology equipment is so trusted.

Mitutoyo's Expertise

When a patient’s quality of life is on the line, there’s no room for error. Mitutoyo metrology solutions can help your manufacturing achieve highly accurate and precise measurements to meet the strictest requirements of medical technology while enabling the latest medical advancements.

Coordinate Measuring Machines for accurate multi-point measurement of artificial joints

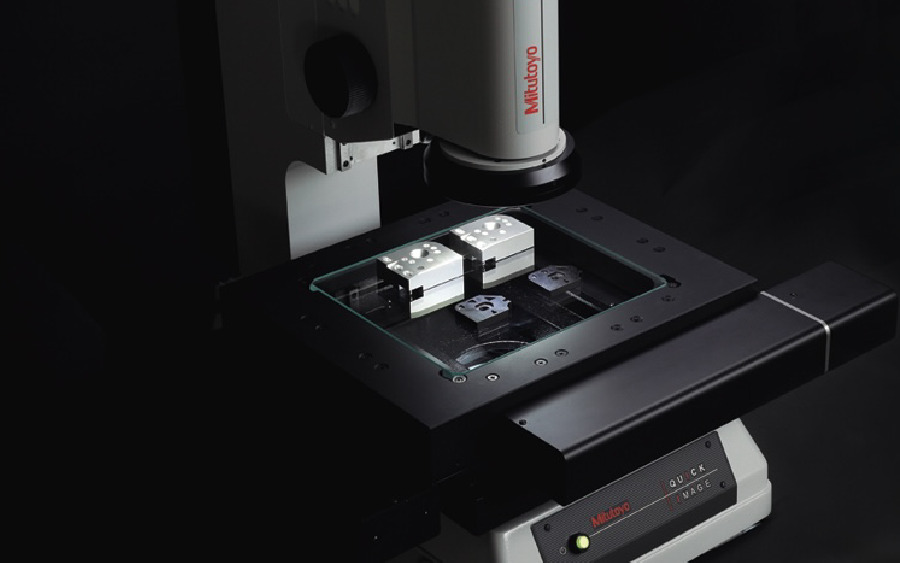

Vision Measurement Solutions for high-speed, non-contact measurement of medical devices and electronics

Form Measurement Solutions for contour and surface finish of knee joints

Medical Metrology Solutions by Mitutoyo

Mitutoyo builds a wide array of highly accurate, best-in-class vision systems for non-contact measurement applications

Capable of both contact and non-contact measurement, our CMM solutions are ideal for 3D inspection

Our form measuring solutions accurately assess complex geometries of any shape, roundness or roughness

Mitutoyo Microscope Monitors Merxin’s Measurements

Merxin is a supplier of both generic and customized inhaler devices and has manufacturing capacity across the globe. See how Merxin uses microscopes from Mitutoyo to help ensure high levels of precision and efficiency in their inspection process.

The Quality Show is an event by Quality that will help connect manufacturing professionals with a growing network of top-tier suppliers and cutting-edge subject matter experts on an array of topics. As the region continues to see massive investments in...

Come find us at Booth #1100 at RAPID + TCT 2026! Here we will be showing off our inspection equipment and metrology solutions.

Join Mitutoyo at “Aviation’s Season Opener” from April 14–19, 2026, in Lakeland, Florida. As the world of aerospace demands absolute accuracy, we’re bringing our latest precision metrology solutions to the 52nd Annual SUN ‘n FUN Aerospace Expo. Visit us in...

Don’t miss the chance to visit our Mitutoyo booth at MRO Americas 2026! From cutting-edge metrology tools to innovative software solutions, we’ve got everything you need to stay ahead of the curve. Join us at MRO Americas and see how...