TRADE IN PROGRAM

Upgrade to Increased Productivity

Why purchase a new system?

• Improve productivity through simplified processes and use of icons.

• Eliminate cost and tedious setup time when measuring multiple features.

• Collision-detection function prevents costly errors and damage to the system, providing peace of mind.

• Ensure full compliance with current ISO standards.

RA-120/P | Entry Level

Best-in-class rotational accuracy for compact roundness measuring instruments.

-Fine adjustment on both X- and Z-axes.

-Multiple analyses through simple operation

-D.A.T. function *except for centering/leveling device: Analog mic-head*

-Scaled Z-axis

-Continuous ID and OD measurement

-Display function for various graphs

-High-precision air bearing

-Wide-range detector

RA-1600M | Intermediate

Equipped with a highly accurate turntable that enables simple and accurate centering and leveling of the workpiece.

-High rotational accuracy (0.03+6H/10000)μm is maintained for an entry level to mid-range model.

-PC-based cylindricity-capable roundtest for both shop floor and laboratory environment.

-Easy-to-use center and level function with mechanical mic heads on alignment table.

-Collision-detection function in detector stops the system, preventing costly error and damage.

RA-2200AS | Advanced

Offering the highest precision level in its class, exceptional ease of use and multifunction analysis capability.

-High-accuracy, manual and automatic centering and leveling turntable.

-Sliding detector-unit holder allows for versatile measurement setups and positions.

-Collision-detection function in detector stops the system, preventing costly error and damage.

-Measurement while tracking is possible through a built-in linear scale in the X-axis. This type of measurement is useful when displacement due to form variation exceeds the measuring range of the sensor, and X-axis motion is necessary to maintain contact with the workpiece surface.

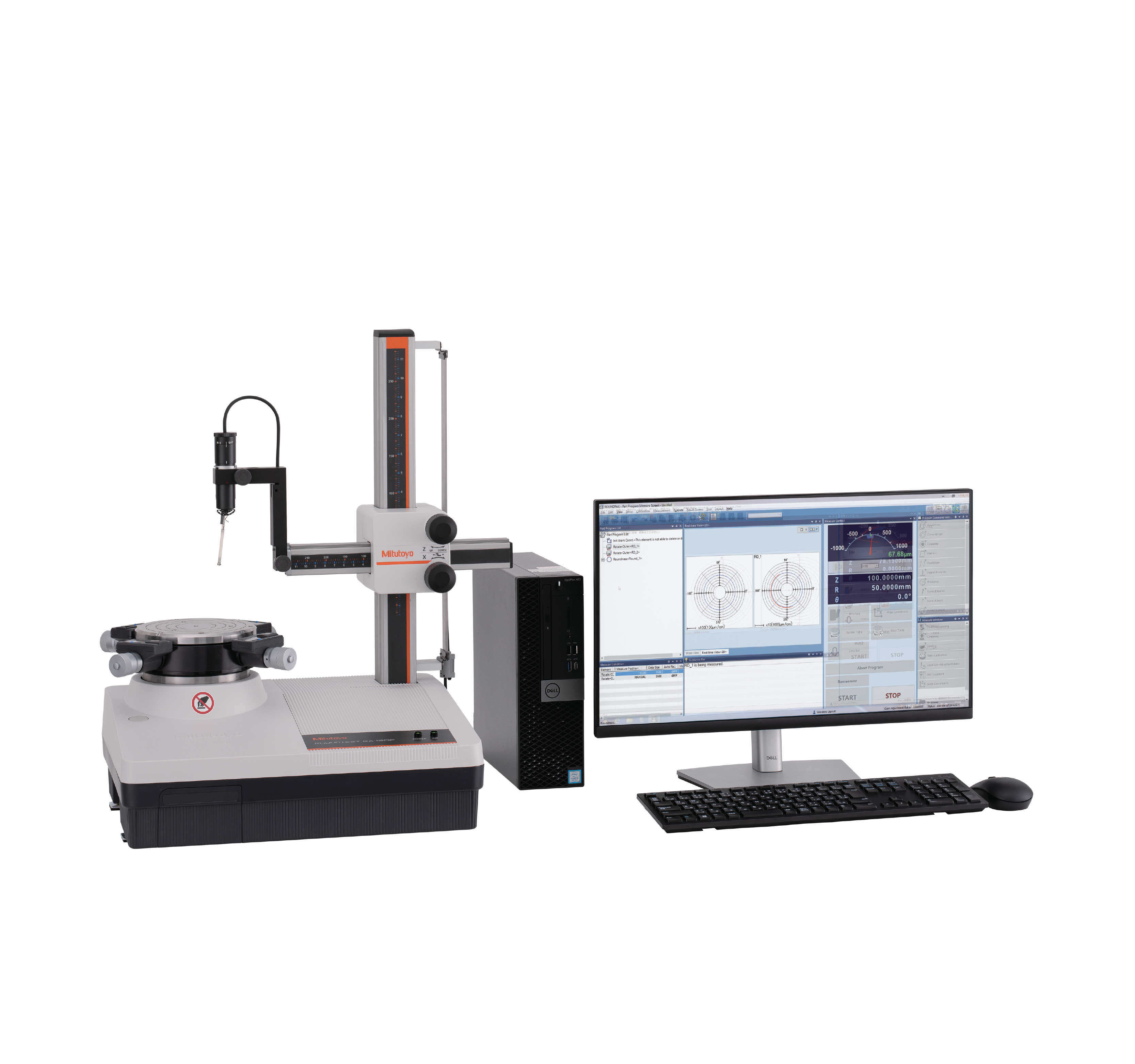

RA-H5200 | CNC

A CNC system combines high accuracy with automatic CNC measurements to improve productivity and efficiency.

-Detector unit orientation programmable for CNC measurement.

-The multi-sensor system is compatible with a standard probe that meets the specifications of the roundness measuring system and an optional surface roughness detector unit.

-Mitutoyo’s linear encoders have been incorporated into the positioning sensors in the X- and Z-axis drive units to directly sense the displacement, thereby achieving highly accurate positioning essential for repeat measurements.

-The RA-H5200 Series is supplied as standard with a high-performance vibration isolator that possesses excellent vibration attenuation.

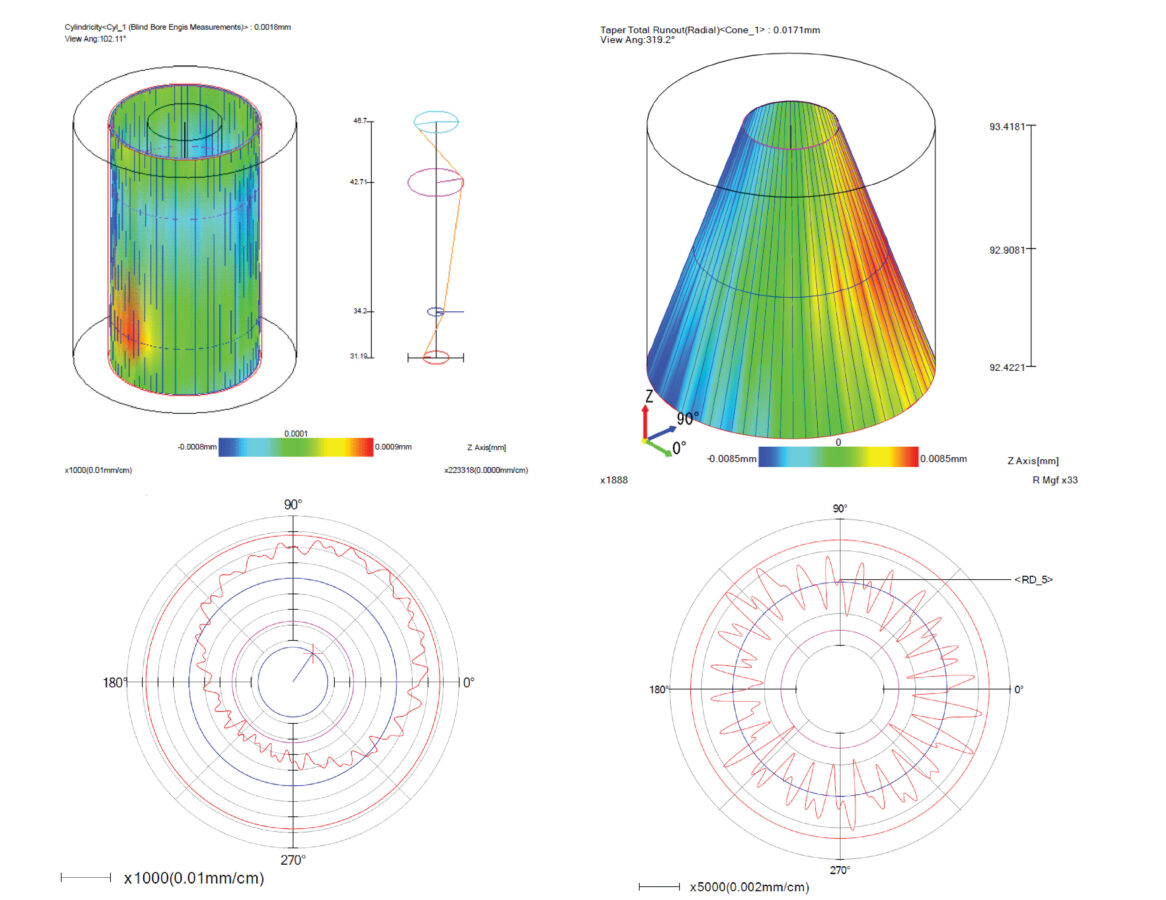

Powered by ROUNDPAK*

Mitutoyo ROUNDPAK measurement and analysis software features an intuitive graphical interface, making the software flexible and easy to use. Windows-based ROUNDPAK simplifies setup and control. ROUNDPAK supports a variety of parameters, including those for roundness/cylindricity, as well as flatness and parallelism. In addition, the program includes an offline teaching function that enables virtual execution of measurement operations in a 3D simulation window. By storing and indexing measurement and evaluation setups, libraries of sequences can be compiled. Custom reports, including depiction of data in 3D graphics, can be easily generated.

*RA-120 uses a dedicated control processing unit.