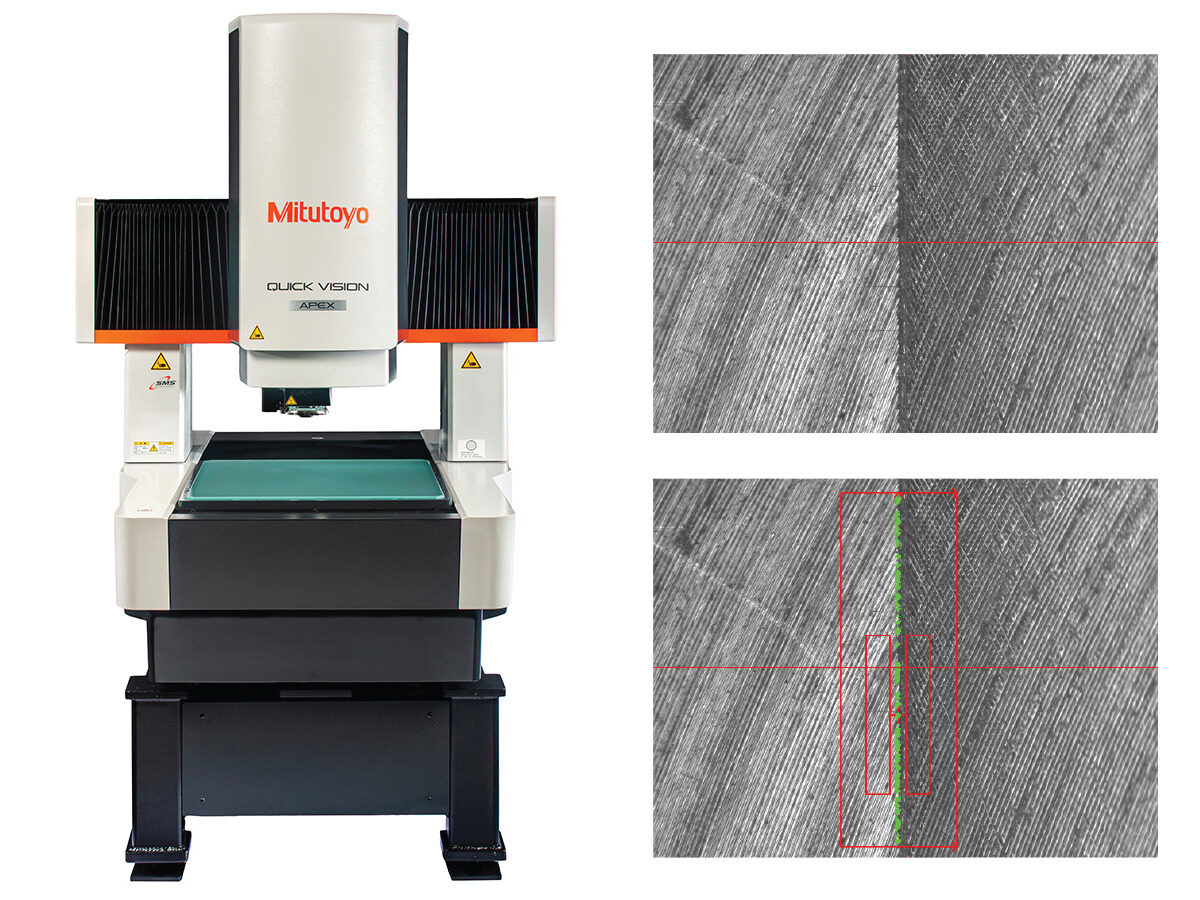

The revolutionary QV-Apex Pro Series is 45% faster than conventional vision systems even when acquiring 3D non-contact measurements. The QV Pro is built with the best available components to provide fast, accurate measurements for many years.

Find the Edge

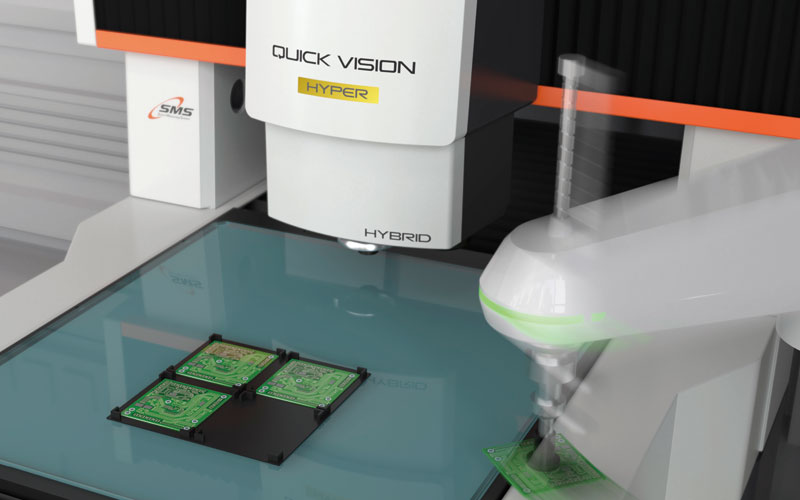

The latest generation of the Mitutoyo Quick Vision Apex Series vision systems are integrated with high-performance technologies and designed for speed, versatility and lasting durability to make highly accurate 3D non-contact measurements a reality. The QV Pro features the best in high-resolution optics and increased image fidelity compared to competitive machines.

STREAM

STREAM is an optional function on the QV-Apex Pro series that delivers amazingly high throughput by taking measurements without stopping the camera. The STREAM function synchronizes the camera motion with the strobe light to capture continuous non-contact measurements with high accuracy and even faster speeds.

StrobeSnap

StrobeSnap is installed on every Quick Vision Pro series model. The StrobeSnap function utilizes a strobe light to reduce image measurement times by shortening the duration the camera is stopped for the image capture. Regardless of the continuity of measuring positions, StrobeSnap helps shorten measuring times by up to 45% over conventional vision measuring systems.

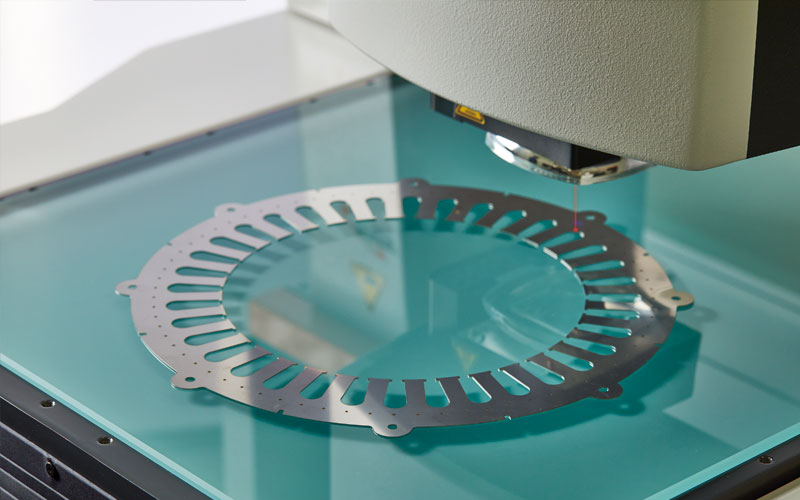

Multiple Hardware Options

QV Apex Pro systems can be equipped with an optional touch probe to capture features on part sides without the need to rotate the part.

![]()

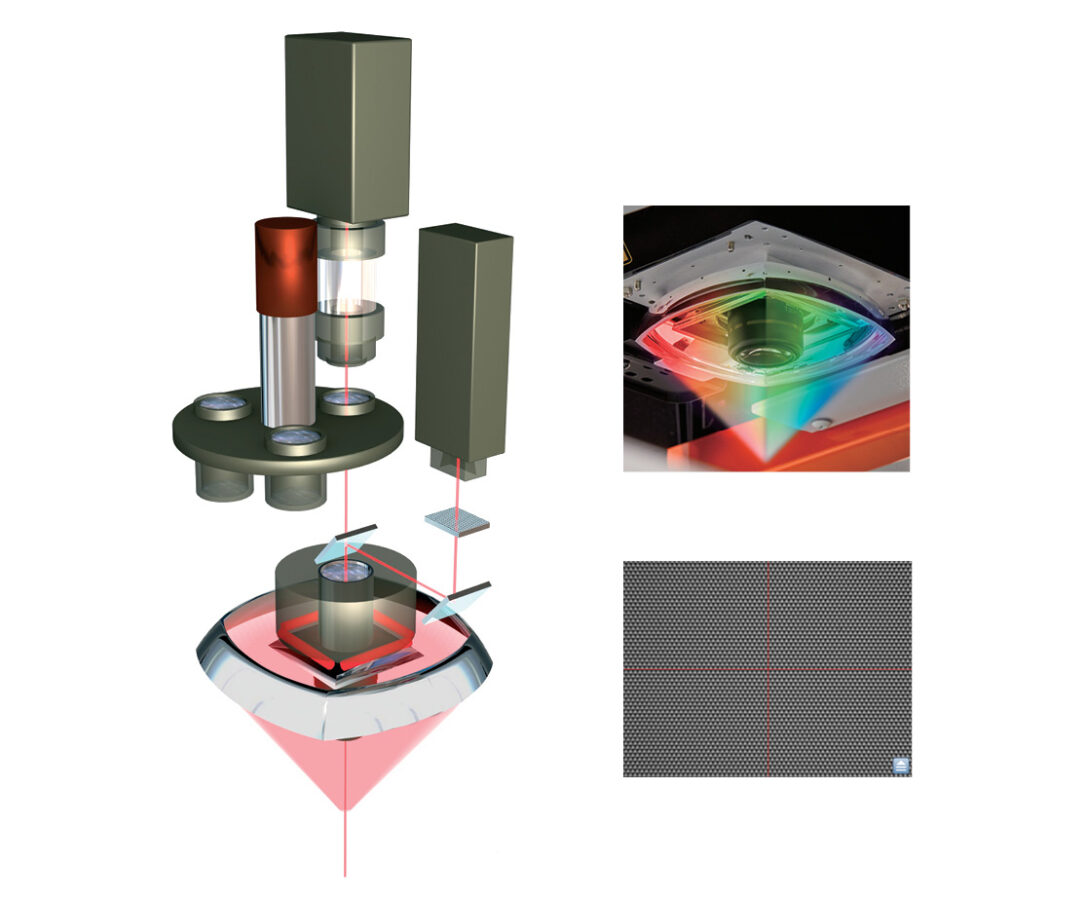

Tracking Auto Focus

The laser automatically keeps parts in focus regardless of shape, eliminating the need to focus and increasing measurement throughput.

![]()

Guaranteed Accuracy

QV Pro systems guarantee the stated accuracy by conforming to ISO 10360-7. Calibration to these standards is available upon request.

![]()

Highly Functional Illumination

The QV Pro Series uses LEDs for all of its lighting sources including the contour, surface and programmable lights. This provides a high-level of light uniformity and responsiveness.

The QV Pro’s advanced image processing technology and versatile measurement tools allow for fast and accurate measurements of various features, such as geometric shapes, angles, and radii. The system’s user-friendly interface and automated measurement capabilities also make it easy to set up and execute measurement routines, improving efficiency and reducing errors, even in smart factories. Overall, the Quick Vision Apex Pro is a powerful and reliable tool that can significantly improve quality control processes, increase productivity, and ultimately help businesses save time and money.

Quality Components & Construction

Advanced optics, high-resolution cameras, and precision motorized stages allow for accurate and repeatable measurements of complex parts. The system also includes a variety of measurement tools, such as edge detection, feature recognition, and geometric measurement to easily capture measurements other vision systems can’t.The system’s robust construction ensures that it can withstand the demand of a busy manufacturing environment to provide highly accurate non-contact measurements for much longer than competing machines. Every component in the QV-Apex Pro is vigorously tested in our own manufacturing facilities to make this series of machines of the most durable, reliable and trusted vision systems on the market.

Service You Can Rely On

Mitutoyo provides a range of services to support users of the Quick Vision Apex Pro including installation, training, calibration and maintenance. Every service offered by Mitutoyo is performed by highly trained and skilled technicians, even on-site training for users to learn how to operate the system effectively and efficiently. Mitutoyo also offers calibration services to ensure the system is functioning at optimal performance.

Easy to Use

An intuitive user interface makes it easy to set up and execute measurement routines, as well as automated measurement capabilities that can improve efficiency and reduce errors. The system’s compatibility with various data analysis and management software makes it easy to integrate into existing quality control processes and data systems.

Automotive

•Flexible measurement of EV parts

•Meet rigorous QC standards

•Enable programming using 3D CAD

•Optimized for advanced part technologies

Aerospace & Defense

•Able to measure small, complex parts like airfoils with high accuracy

•Touch-probe capabilities offer great versatility to take difficult measurements faster

•Required high-precision resolution is available on all 3 axis

Medical

•High accuracy for ultra-small devices

•Ensure quality of advanced manufacturing

•Up to 4800X optical magnification

•High accuracy 3D measurement

Semi-Conductor

•Continuous measurement in mass production

•Prevent nonconformities on the fly

•3D measurement with multiple sensors

•Detect contaminants, burrs & cracks

Have a Legacy Vision Measuring System?

Mitutoyo offers a special trade-in trade up program for your old vision machine. With this program, you can get a credit toward a new QV-Apex Pro system, and we will remove your old vision system and haul it away.