Automotive manufacturing has always been at the forefront of industrial innovation, and the wide range of automotive measurement solutions from Mitutoyo pave the way for tomorrow’s advancements. From handheld gaging to 3D and optical measurement solutions, Mitutoyo provides the inspection and scanning capabilities you need for improved performance.

Automotive Industry Realities

The automotive industry’s metrology needs vary widely, encompassing dimensional and form measurement, near-line and in-line applications, complex geometries as well as manual and automated inspection. Manufacturers must find reliable, tailored products and solutions to gather the measurement data they need—and seamless ways to integrate and analyze it.

Shrinking Production Cycles

As design-to-production cycles shrink and automotive components become more sophisticated, manufacturers must find a way to increase throughput and efficiency without compromising the comfort, safety or capability of the vehicles they produce.

Multiple Integrations

Testing the various components in today’s connected vehicles requires a broad range of measurement solutions, from precision measuring tools to large CMMs, vision measurement systems and data management. To accurately evaluate a vehicle, manufacturers must seamlessly integrate data from these disparate products and solutions.

Mitutoyo’s Expertise

Mitutoyo is proud to be the metrology partner of automotive manufacturers around the world. Our broad range of solutions includes instruments for almost any measuring need, integrated through our MeasurLink® data-management software.

Full range of solutions: near-line and in-line, contact and non-contact

Automated measurement to improve repeatability and speed throughput

Coordinated software to integrate and analyze measurement data

Automotive Measurement Solutions by Mitutoyo

Our form measuring solutions accurately assess complex geometries of any shape, roundness or roughness

Easily manage your measurement data using a Mitutoyo data management system powered by MeasurLink® software

Capable of both contact and non-contact measurement, our CMM solutions are ideal for 3D inspection

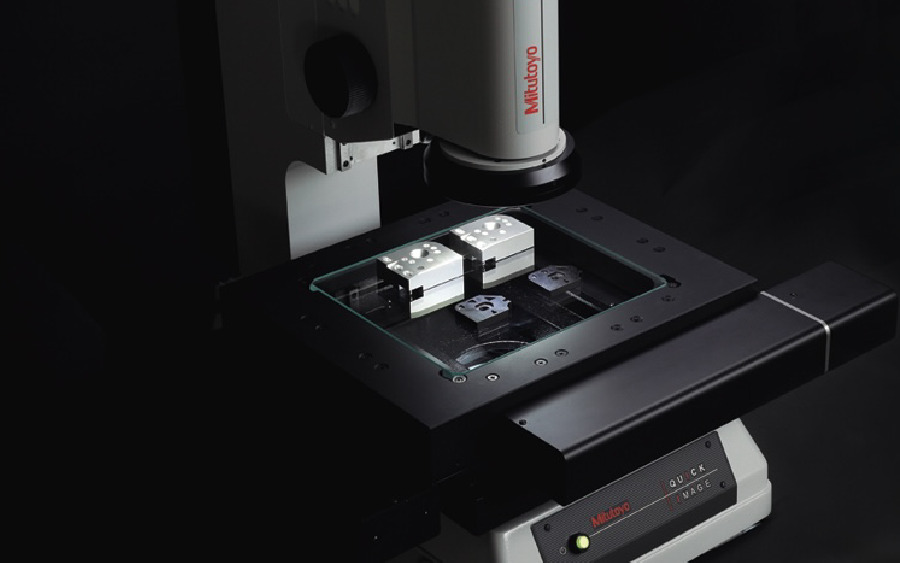

Mitutoyo builds a wide array of highly accurate, best-in-class vision systems for non-contact measurement applications

Our high-resolution microscopes and profile projectors measure minuscule electronic components with high accuracy and repeatability

As an industry-leading provider of contact and non-contact sensor systems, Mitutoyo supports your strictest measurement needs

Our accurate, user-friendly testing equipment solutions set the industry benchmark for most standardized testing methods

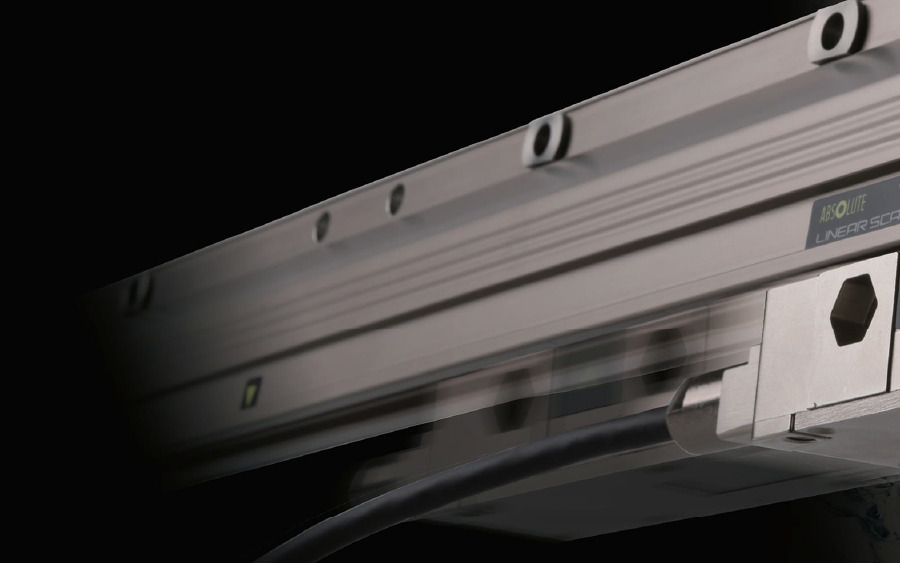

Mitutoyo digital and linear measurement tools deliver ultimate precision, accuracy to in-house machine tool applications and manufacturing

The Total Package for Automotive Metrology

By incorporating a CNC setup, Advics Manufacturing Ohio, Inc. was able to dramatically transform contour measurement of automotive brake components from a 45-minute specialist’s task, to a 3 1/2-minute generalist’s job. Find out how the team at Mitutoyo delivered for this quality-leader in brake products.

The Quality Show is an event by Quality that will help connect manufacturing professionals with a growing network of top-tier suppliers and cutting-edge subject matter experts on an array of topics. As the region continues to see massive investments in...

Come find us at Booth #1100 at RAPID + TCT 2026! Here we will be showing off our inspection equipment and metrology solutions.

Join Mitutoyo at “Aviation’s Season Opener” from April 14–19, 2026, in Lakeland, Florida. As the world of aerospace demands absolute accuracy, we’re bringing our latest precision metrology solutions to the 52nd Annual SUN ‘n FUN Aerospace Expo. Visit us in...

Don’t miss the chance to visit our Mitutoyo booth at MRO Americas 2026! From cutting-edge metrology tools to innovative software solutions, we’ve got everything you need to stay ahead of the curve. Join us at MRO Americas and see how...