New Functions & Specification Changes in GEARPAK Express include:

- GEARPAK now supports ISO 1328 ed. 2013, JIS B 1702 ed. 2016, and ANSI/AGMA 2015, enabling tolerance, error, and class value calculations, as well as measurement data filtering.

- Simplified Coordinate System Settings: The X-axis can be automatically set by positioning the probe near the tooth tip, simplifying the setup process.

- Profile and Lead Error Average Graph: This new graph helps users check for gear trend errors.

- Dimension Over Balls Evaluation: New method added for spur gear evaluation.

- Single Flank Rolling Test: Now included in the GEARPAK Cylindrical function.

- Custom Stylus Builder Support: Allows for multiple probe configurations.

GEARPAK Express

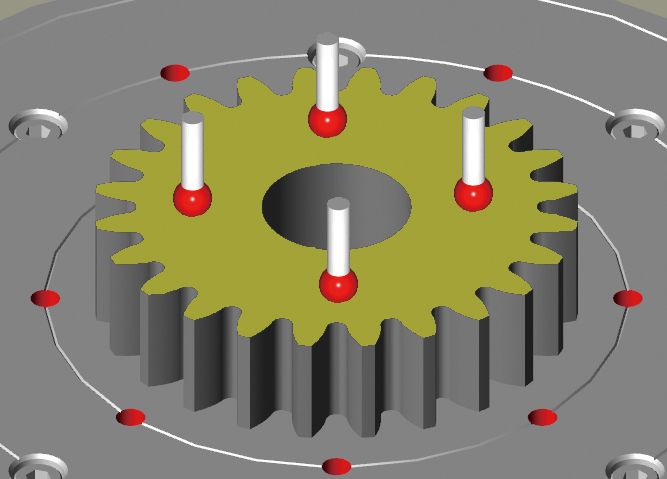

Cylindrical gears with an involute tooth shape can be measured with GEARPAK-Express. The modern GUI based on the 3D model of the gear, makes GEARPAK Express extremely easy to use. GEARPAK Express supports 4-axis nominal scanning which, in combination with a rotary table, can reduce the measurement time up to 50% * compared with the conventional method. *depending on the gear size and required accuracy

Why Choose GEARPAK Express?

GEARPAK Express allows for faster 4-axis scanning, reducing measurement time while boosting throughput. Its automated setup feature simplifies complex gear measurements on a CMM, saving operator time and reducing workload. GEARPAK’s intuitive interface also minimizes operator training time while further streamlining workflow to save valuable time and money.