Over the past 40 years, Exeter, Devon based Rotamic Engineering Ltd has established an excellent reputation for the manufacturing of precision machined components. In addition to serving the demanding Defense, Formula 1 and Medical industries, Rotamic has supplied customers in the Aerospace industry for more than 20 years, this challenging field currently constitutes the company’s largest market sector. To meet the requirements of its Aerospace based clients, in addition to ISO9001, Rotamic Engineering obtained the Aerospace standard AS9100 in 2006. Given the demanding nature of the industries it serves, the pressure to present the most competitive of quotes and the need to consistently deliver premium quality components in a timely manner, the company’s main drivers include efficiency and quality. Operating from a large manufacturing facility designed and built to Rotamic’s specification, to help drive the business forward and to remain competitive in the global market place, the company has continually invested in advanced CNC machine tools and have adopted the latest metrology equipment, tooling and software.

Over the past 40 years, Exeter, Devon based Rotamic Engineering Ltd has established an excellent reputation for the manufacturing of precision machined components. In addition to serving the demanding Defense, Formula 1 and Medical industries, Rotamic has supplied customers in the Aerospace industry for more than 20 years, this challenging field currently constitutes the company’s largest market sector. To meet the requirements of its Aerospace based clients, in addition to ISO9001, Rotamic Engineering obtained the Aerospace standard AS9100 in 2006. Given the demanding nature of the industries it serves, the pressure to present the most competitive of quotes and the need to consistently deliver premium quality components in a timely manner, the company’s main drivers include efficiency and quality. Operating from a large manufacturing facility designed and built to Rotamic’s specification, to help drive the business forward and to remain competitive in the global market place, the company has continually invested in advanced CNC machine tools and have adopted the latest metrology equipment, tooling and software.

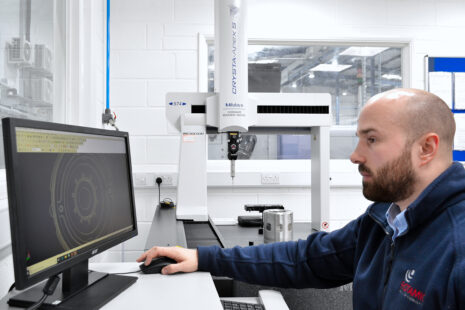

The highest quality standards are achieved by the application of the company’s strict quality regime and Rotamic’s adherence to its standards and certifications. In addition to ensuring that all materials are traceable and sourced from approved suppliers, throughout each manufacturing stage in-process quality checks are made by the company’s machine operators, finally, before component dispatch in-depth final inspection routines are carried-out. To ensure that Rotamic’s important inspection provision was able to keep pace with the company’s recent significant rise in production levels, a search was made for an advanced Coordinate Measuring Machine (CMM) that could satisfy the company’s twin aims of efficiency and quality. Having examined the market, the answer was found in a CRYSTA-Apex S574 CNC CMM from Mitutoyo UK.

Rotamic’s Quality Engineer, Kai Kidson explained. “We are a specialist precision engineering company manufacturing a diverse range of components for customers involved in a variety of industrial sectors – primarily aerospace, but also medical, laser instrument, high vacuum, defense and oil and gas. We use a wide range of advanced, high-yield, CNC machine tools that are operated by our highly skilled workforce. We have achieved AS9100, BS EN 1509001, OHSAS 18001 and BS EN ISO 14001 certification. Faced with the need to improve our important CMM inspection capacity so that it could keep-pace with increased levels of production, we considered several CMM options and took advice from our customers. In addition to Mitutoyo CMMs being recommended by the majority of our customers, each spoke highly of the levels of service provided by the company. Also, an excellent practical demonstration at Mitutoyo’s Andover HQ, persuaded us that the company’s CRYSTA-Apex 5574 CNC CMM was ideal for our use.”

“When compared to the other CMMs we looked at, we considered that the impressive accuracy and repeatability of the Mitutoyo CNC CMM would provide us with the capability to inspect our components with the most challenging of dimensional specifications. Also, not only would the speed and efficiency of the machine be able to keep-pace with our current levels of production, we believed that it should be able to cope with all foreseeable rises in production. Having now dedicated our previous CMM to use by our machine operators, our new CRYSTA-Apex, recently installed in our environmentally controlled inspection department, is now delivering on all of the promises made by Mitutoyo UK. Our new Mitutoyo CMM is proving easy to use and able to inspect our most complex, high-precision parts with great speed and efficiency. In addition to inspecting single parts, we are able to place a large batch of components on to the CMMs granite bed, recall a prewritten program and perform a highly-efficient mass inspection routine in a fast, fully automatic CNC mode. We are then able to generate comprehensively detailed inspection reports that can be archived for our important traceable records.”

Mitutoyo’s CRYSTA-Apex S Series of high performance, cost effective CMMs are designed and constructed according to the company’s unmatched experience in CNC CMM technology. Manufactured from advanced lightweight materials and boasting an innovative machine structure, the CRYSTA-Apex S Series delivers high motion stability, impressive levels of speed and accuracy and excellent affordability. Ideal for use within dedicated inspection departments or on the shop floor, the advanced CMM series feature a temperature compensation function that allows users to make accurate measurements in less than perfect environments.

To enable each customer to receive a CMM to match their exact needs, the CRYSTA-Apex S Series is available in a wide range of capacities. Also, the availability of a wide range of Mitutoyo vision and scanning probe technologies allows these advanced machines to be further tuned to all users’ needs. In addition to first-class hardware, Mitutoyo CMMs boast comprehensive analysis software for interpreting measurement results in the timely manner so essential for keeping up with today’s fast-paced production.