Experience the speed, efficiency and precision of advanced contour and surface roughness measurement in one machine, with the new FORMTRACER Avant Series hybrid measuring system.

A range of models covers every purpose

FORMTRACER Avant Series allows a contour instrument or surface roughness tester to be upgraded from a general-purpose instrument to a high-precision contour instrument. Three types of surface roughness detector holders can be added for a wider range of measurements.

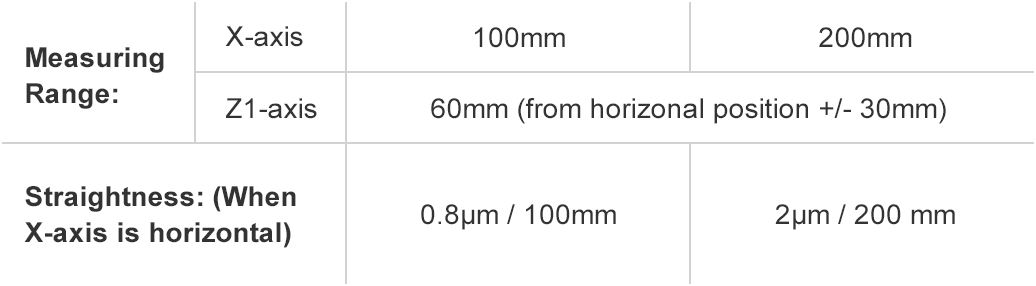

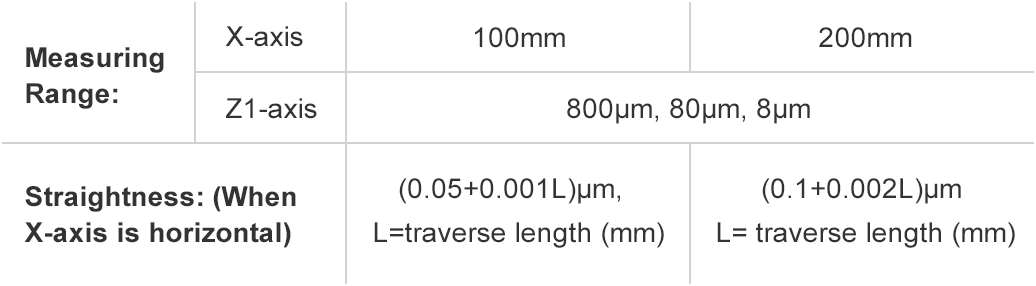

Contour Instruments FTA-S4C3000/4000

Surface Roughness Tester FTA-S4S3000

Hybrid measuring system for both contour and surface roughness FTA-S4D4000

200mm drive unit available in large base and high column models FTA-L8S3000 and FTA-H8S3000

Conversion between contour and surface roughness measurement happens within seconds by simply replacing the mounted detector, without shutting down software or switching off the controller.

Contour

Surface Roughness

Precise measurements for practically any workpiece

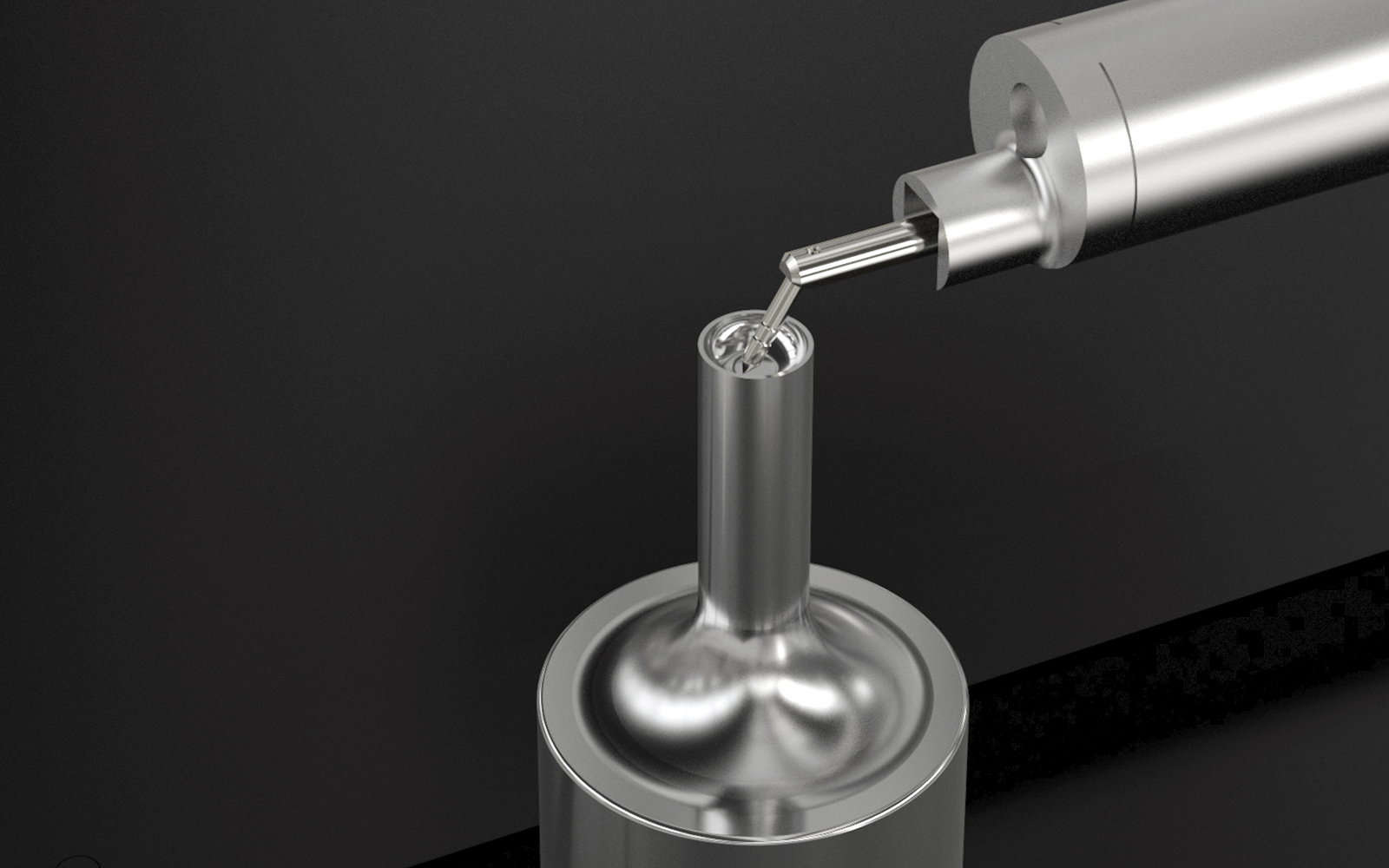

PET bottlesThe thread of a PET bottle requires precision measurement, since leaks will occur if it is too loose, or the cap cannot be tightened if it is too tight. The “sectional form of thread” of such PET bottles can be measured without cutting the product by using a cone stylus.

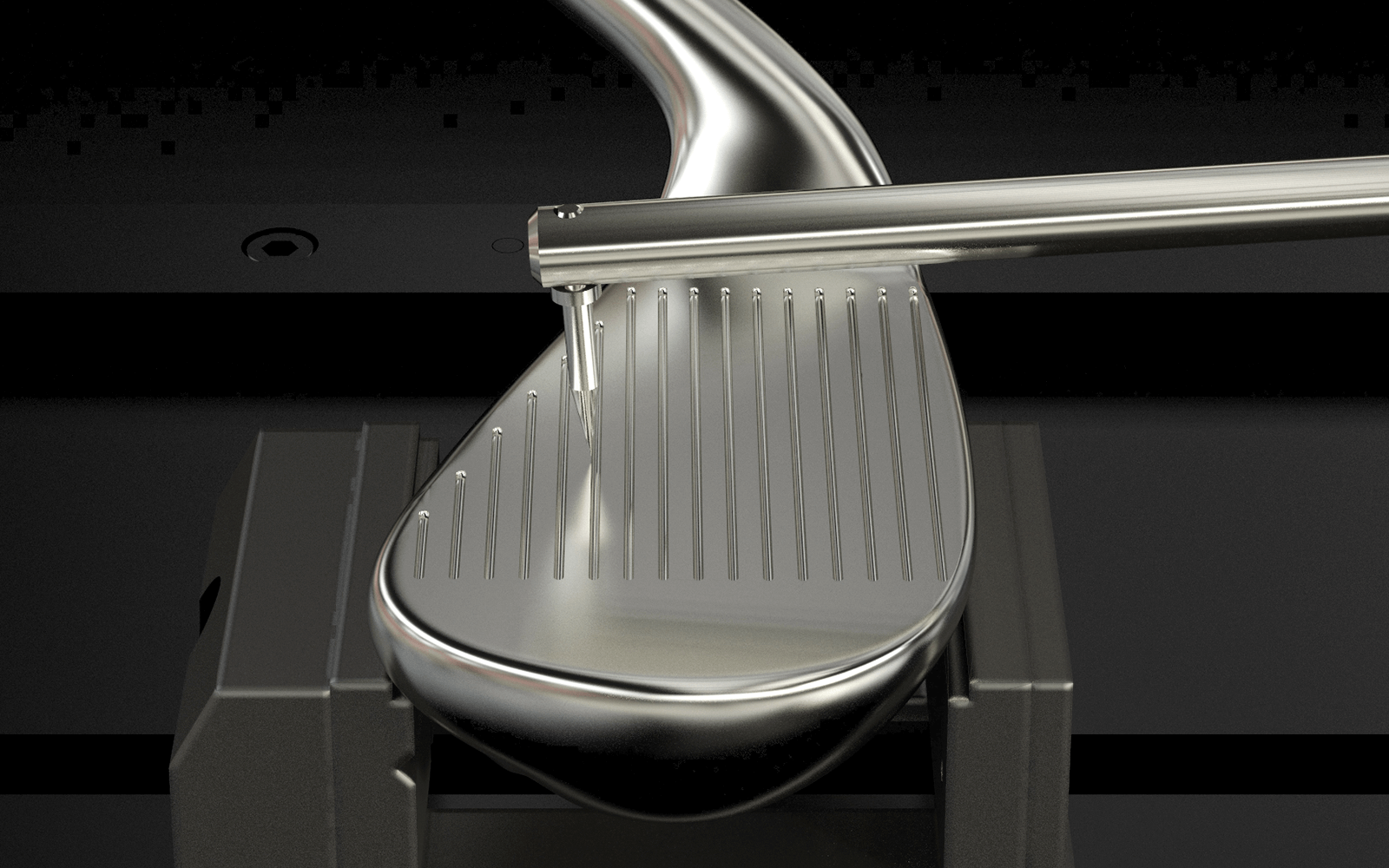

Golf club face groovesGroove pitches, groove intervals, and edge shapes are strictly determined by golf club standards. By using the part-program as a standard feature and automating analysis, efficient evaluation is possible with precision measurement.

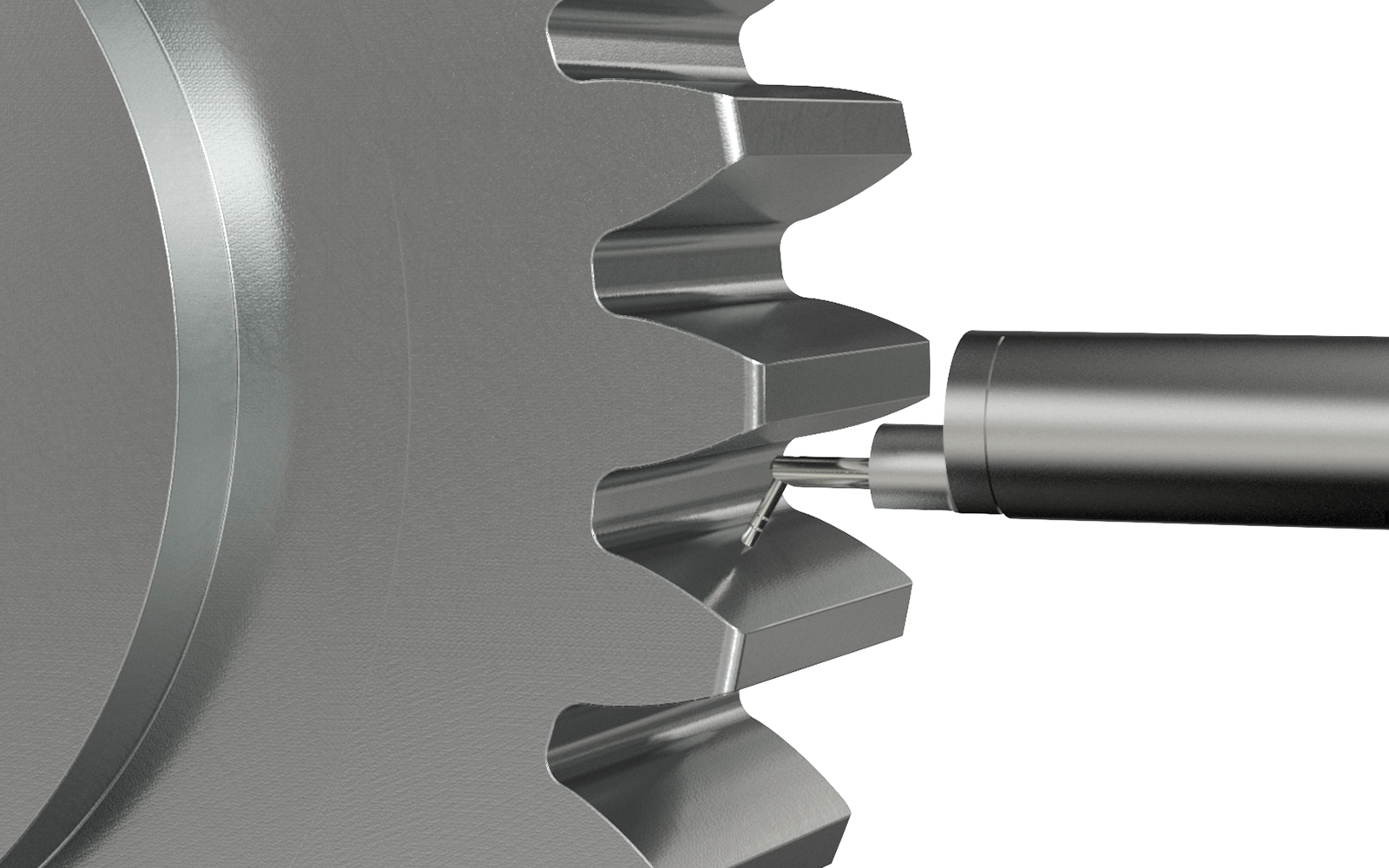

Tooth faces of gearsBy using a stylus for gear teeth, it is possible to measure over the full face of a tooth, right down to the root. FORMTRACER Avant Series, which can cut off the positioning distance to its limit (0.05 mm) helps evaluate the surface roughness of gear teeth

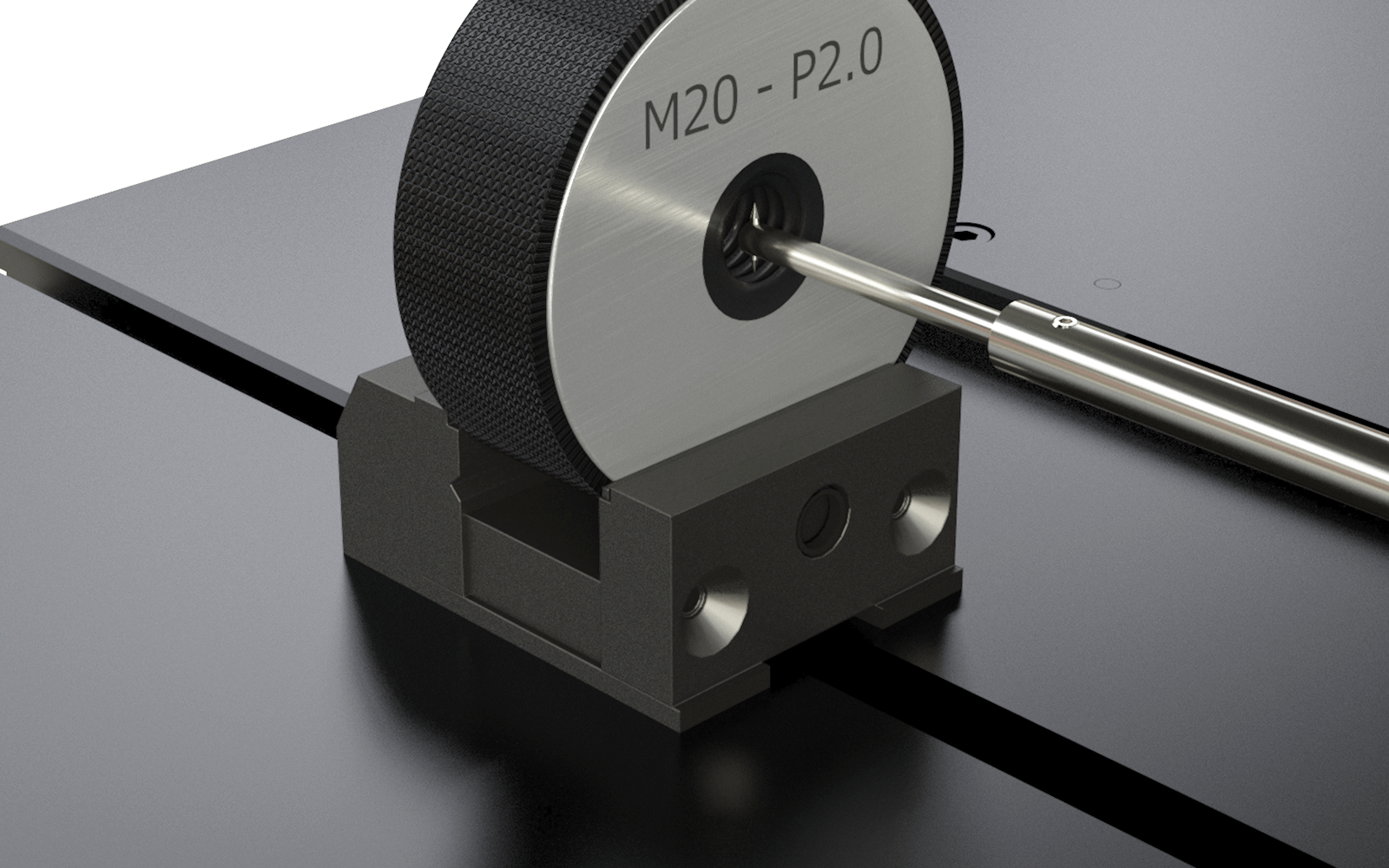

Screw gauge ringsUpper/lower surface continuous measurement and measurement adjustable feature on the C-4500 detector allows simultaneous measurements of the effective diameter of screw or ring gages, together with thread angle and pitch.

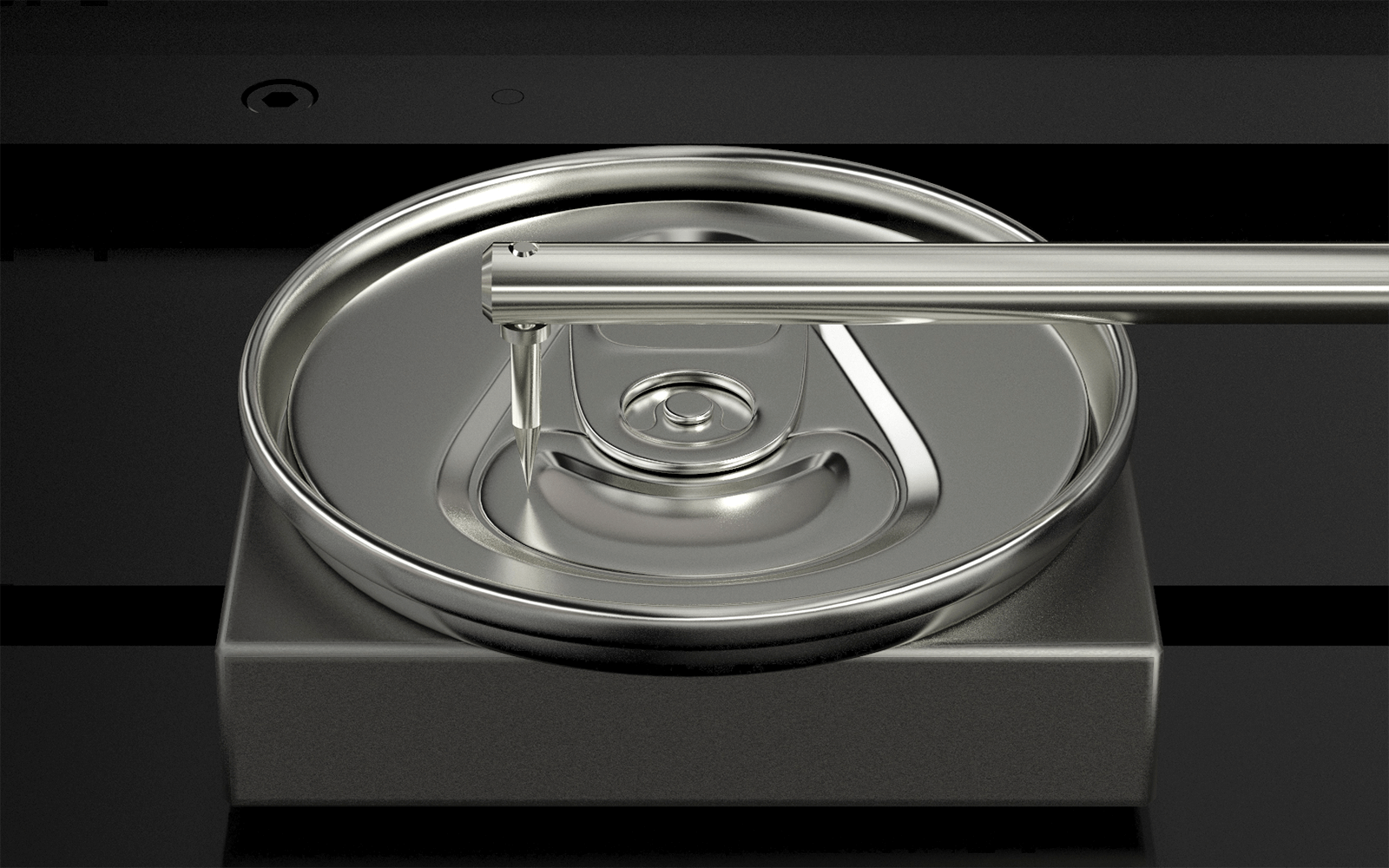

Can pull-topsIf the pull-top groove is too shallow, the pull-top cannot be opened, and if it is too deep, it will be opened easily, resulting in leakage. The groove dimensions of products can be efficiently controlled where high accuracy is required.

Tablet moldsDurability is required for tablet molds to ensure the detachability of pharmaceutical powder and reduction of production cost. FORMTRACER Avant Series helps evaluate the surface roughness of molds with high accuracy from edge to edge.

High-Speed efficiency drastically reduces set-up time

| FEATURES: | BENEFITS: |

|---|---|

|

Best-In-Class

High-Speed Drive |

|

| Retraction Speed |

The stroke (retraction) speed is improved by approx. three times compared to conventional models, significantly improving measuring efficiency. |

|

Positioning Distance

|

Industry-leading positioning distance from the start of measurement to the start of data acquisition is reduced to the absolute minimum of 0.05 mm. |

Versatile features for superior operability

| FEATURES: | BENEFITS: |

|---|---|

|

X-axis Inclinable Drive Unit |

Efficiently measure inclined surfaces within a range of ±45° without added fixtures or positional adjustments. |

| Arc Scale | Built-in precision arc scale allows the circular trajectory of the stylus tip to be read directly, eliminating the need for an arc direct conversion mechanism. |

| Cable-Less | All cables are housed inside the main unit to eliminate any risk of abrasion or snagging and guarantee precision measurement and rapid movement. |

| Sensor Exchange | Replace contour or surface detector without turning off the controller power, reducing measuring time by approx. 30 seconds. |

| Upper/Lower Surface Continuous Measurement | Double-sided conical stylus continuously measures upper/lower surfaces, facilitating difficult processes such as diameter measurements of an internal screw thread. |

|

Advanced Remote Control Box |

Provides maximum ease of use while new function keys support fast creation of measurement part programs for maximum productivity. |

| Stylus Drop Detection | Immediately stops operation if the stylus suddenly drops, preventing damage to the stylus without relying on a conventional mechanical stop. |

Explore how FORMTRACER Avant reduces set-up time and improves efficiency by integrating contour and surface roughness measurements into one machine.

Software

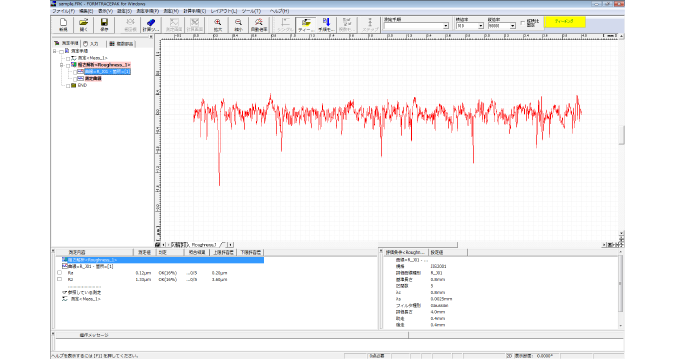

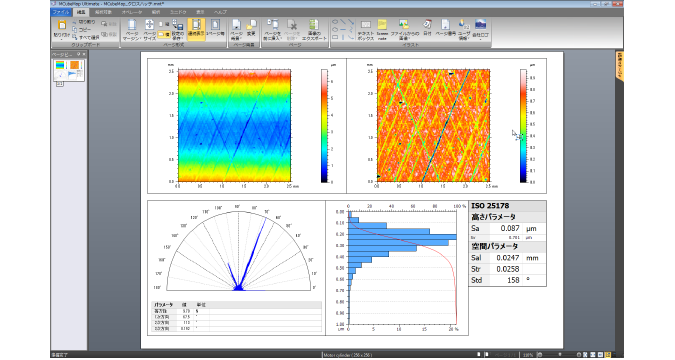

FORMTRACER Avant Series comes with feature-packed software to streamline efficiency, improve quality and prevent defective products.

Provides total support for controlling the measuring system, system roughness analysis, contour analysis, contour tolerancing and inspection report creation.

Simple and efficient application software for 2D/3D analysis. Data for analysis is imported from the Surface Roughness Measuring System.

Networks each measurement system and aggregates the measurement data in a server.

Request an assessment

Discover the multiple advantages of combined contour and surface roughness measurement. Schedule an in-person demo or virtual assessment to see the new FORMTRACER Avant Series in action.